Vibrating Deck Screens are available with any style of edge preparation or hook strip, ready for field installation upon delivery.

Proper screen tension is crucial for effective screening and longer screen life. Our edge preparations fit the deck properly for easy screen installation and tensioning.

Banded Hook edges increase strength (prevent flattening) and eliminate mesh pull-out on fine wire mesh or high tension screens.

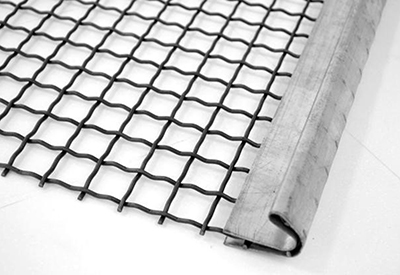

Woven vibrating screen mesh is also called quarry screen mesh, crusher screen mesh. It is made of spring steel wire (high carbon steel wire, medium carbon steel wire, manganese steel wire) and stainless steel wire.

It has different weaving types and edge preparations. The main weaving types are flat top and crimped. Crimped type can be divided into single wire crimped and double wire crimped.

The high quality raw materials makes woven vibrating screen mesh have many features, such as high tensile, wear, temperature and weather resistance and so on.

With so many features, the woven vibrating screen mesh is used on vibrating machines in screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mining, quarry, aggregate production industries.

Hardware Wire Mesh Co., Ltd specializes in High Carbon Steel Screen Mesh, designed for optimal performance in vibrating screen machines. This mesh excels in filtering and separating a variety of materials, including sand, gravel, coal, and rocks. Crafted from robust materials such as high tensile spring steel, manganese steel, and stainless steel, the mesh is engineered to withstand damage and maintain its shape under diverse conditions. Its versatility is evident in its ability to operate effectively across a spectrum of temperatures. The product range encompasses a variety of styles, including woven wire, self-cleaning, piano wire, and stainless steel screen mesh, catering to a broad range of industrial needs. JD Hardware Wire Mesh Co., Ltd focuses on delivering quality and durability, ensuring that their High Carbon Steel Screen Mesh stands up to the demands of various screening applications.

Detailed Specifications of High Carbon Steel Screen Mesh

Material Quality and Options: The mesh is available in two high-grade materials, High Tensile Spring Steel, known for its exceptional strength and flexibility, 65Manganese Steel, recognized for its high impact resistance and durability.

Wire Diameter Versatility: The wire diameter of this mesh ranges from a fine 1.0mm to a robust 14mm. This range allows for a wide spectrum of applications, from delicate screening to heavy-duty filtering.

Aperture Size for Precision Screening: Aperture sizes are varied, ranging from as small as 2.0mm to as large as 100.0mm. This diversity in aperture size makes the mesh suitable for a variety of screening tasks, from fine sand to larger rocks.

Width Options for Diverse Applications: Standard widths offered include 1.22m, 1.53m, 1.83m, and 2m. Custom widths are available to meet specific project requirements, enhancing the product’s adaptability to different screening machines and environments.

Length Customization: The length of the mesh can be tailored, starting from 1.22m and extending up to 6m. This flexibility in length ensures that the mesh can be customized for large-scale industrial uses or smaller, specific projects.

Size:

| Chemical sheet of the main material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel Grade | Chemical Composition (%) | ||||||||

| China (GB - YG) | USA (AISI) | C | Mn | Si | S | P | Cr | Cu | Ni |

| # 45 | 1045 | 0.42 - 0.50 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 50 | 1050 | 0.47 - 0.55 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 55 | 1055 | 0.52 - 0.60 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 60 | 1060 | 0.57 - 0.65 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 70 | 1070 | 0.67 - 0.75 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| 65 Mn | 1566 | 0.62 - 0.70 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

Weave Types of High Carbon Steel Screen Mesh

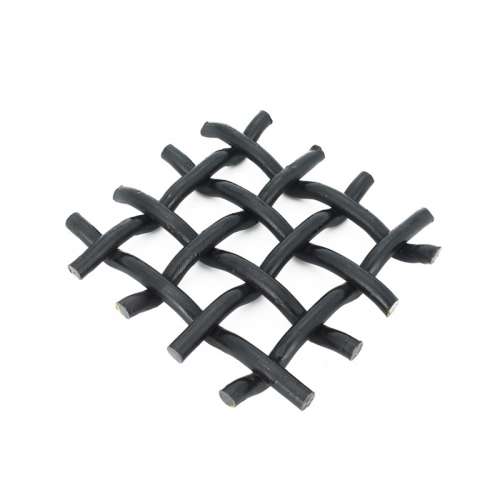

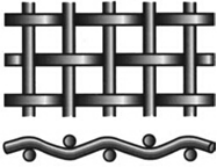

Double-Crimp Weave:

The Double-Crimp weave is a versatile option featuring smaller, uniform openings. This style is renowned for its all-around efficiency and long-wearing performance, making it suitable for a broad range of applications. Its tight crimping provides stability and strength, ensuring the mesh holds its form under various stresses, thus ideal for applications where precision and durability are critical.

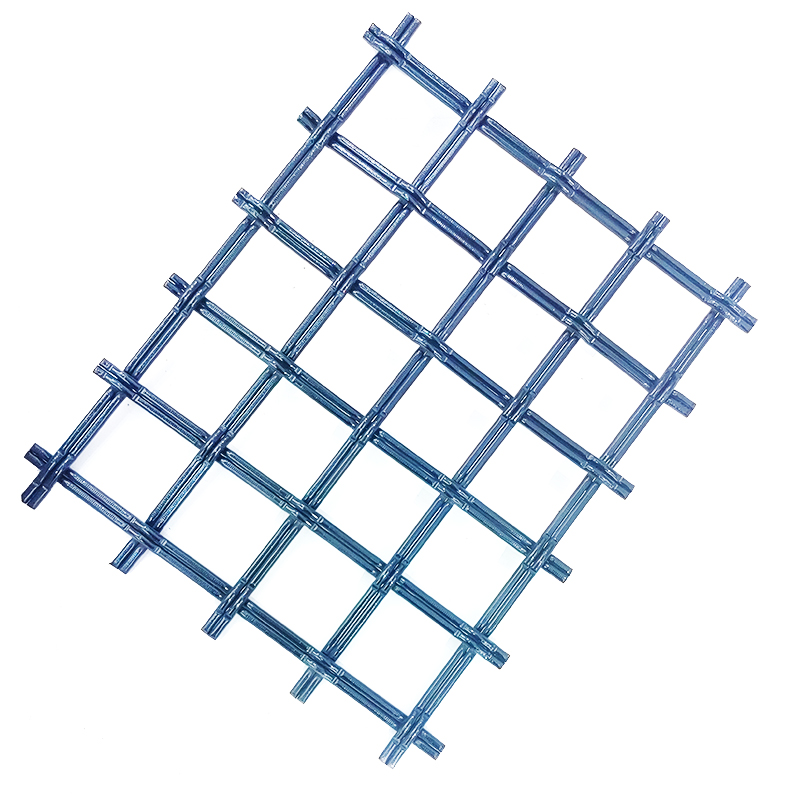

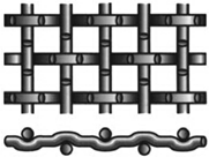

Lock-Crimp Weave:

Lock-Crimp weave is characterized by its larger openings, designed specifically for heavy-duty and scalping applications. In this weave, the wire is firmly locked in place, a feature that not only contributes to the longevity of the screen but also maintains accurate opening sizes over time. This makes it an excellent choice for applications that require durability and consistent performance, especially in demanding environments where wear and tear are significant concerns.

Slotted Openings Weave:

The Slotted Openings weave, featuring single-shute oblong openings, is expertly designed to address minor blinding issues, thereby enhancing material flow. This weave type is especially beneficial in applications where unimpeded flow is essential and minor particles can cause clogging. The unique shape of the openings facilitates better flow and is ideal for specific applications where standard square or rectangular openings might not be as effective.

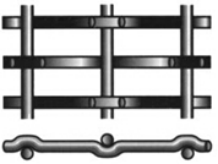

Flat Top Weave:

Flat Top weave offers a smoother, flatter surface compared to other weave types, which can significantly improve material flow. This characteristic makes it particularly suitable for applications where a smooth surface can aid in the seamless movement and processing of materials. The flat top weave is often chosen for its ability to facilitate easier movement of materials over the screen, making it a preferred choice in industries where efficient material handling is a priority.

Applications

Woven vibrating screen mesh can be used as screen deck in quarry screen and crusher screen to separate and sort stone, sand, gravel, coal, rock and other materials. It is widely used in the large scale stone processing, asphalt mixing plants, coal, metallurgy, chemical and other industries.

Weave Styles

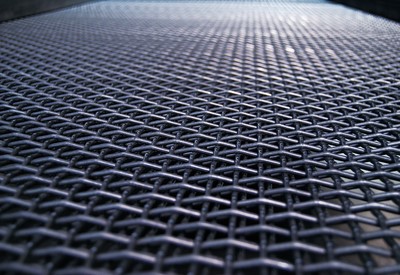

Plain Weave/ Double Crimp Woven Wire

The advantages of plain weave woven wire mesh are simplicity and high weave precision. This type of weave is used where the opening is relatively small, can guarantee achieving high efficiency and sustained performance screening.

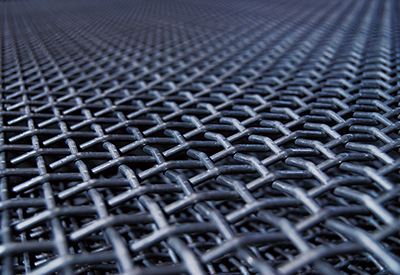

Lock Crimp Woven Wire

In the lock crimp weave type, weft and warp wires pass each other and get locked together at the point of intersection. The crimping is done to lock the wires to prevent from abrasion caused by wire movements. This weave type works perfectly for screening applications where the aperture size and wire diameter are relatively large.

Flat Top Woven Wire

The flat top weave offers a smooth surface for easier material flow. This type of woven wire provides long abrasion resistance lifetime since there are no obstacles on the smooth surface side to strike the material during its flowing.

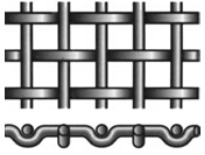

Intercrimp Woven Wire

Intermediate crimp, or simply intercrimp has extra crimps in warp and weft wires between the intersections, it is primarily used where larger aperture size is required while the wire diameter remains stable. The rigidity and stability are greater than common woven wire screen.

Thanks to its feature of large open area, the intercrimp woven wire screen is ideally suited for use in applications with high throughput.

Applications

Square wire mesh is mainly used as screens in various industries, such as mining, quarrying, screening plates, crushing screens, drum screens, vibrating screens, and screens used in road construction equipment or asphalt mixing equipment. And many more industries, including chemical, pharmaceutical, security and protection, construction, etc.