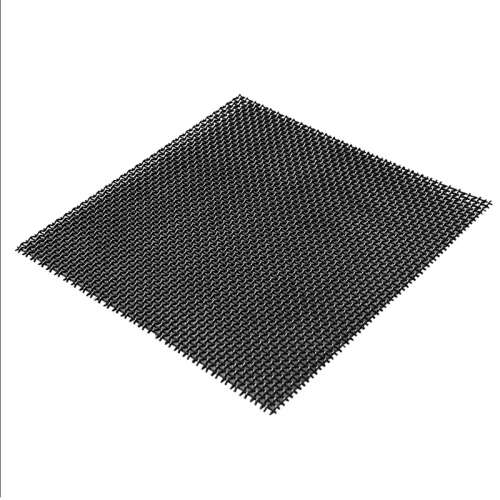

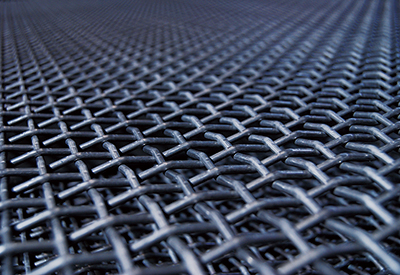

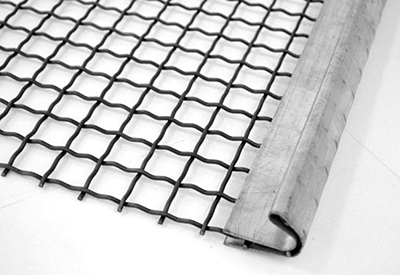

Woven vibrating screen mesh is also called quarry screen mesh, crusher screen mesh. It is made of spring steel wire (high carbon steel wire, medium carbon steel wire, manganese steel wire) and stainless steel wire.

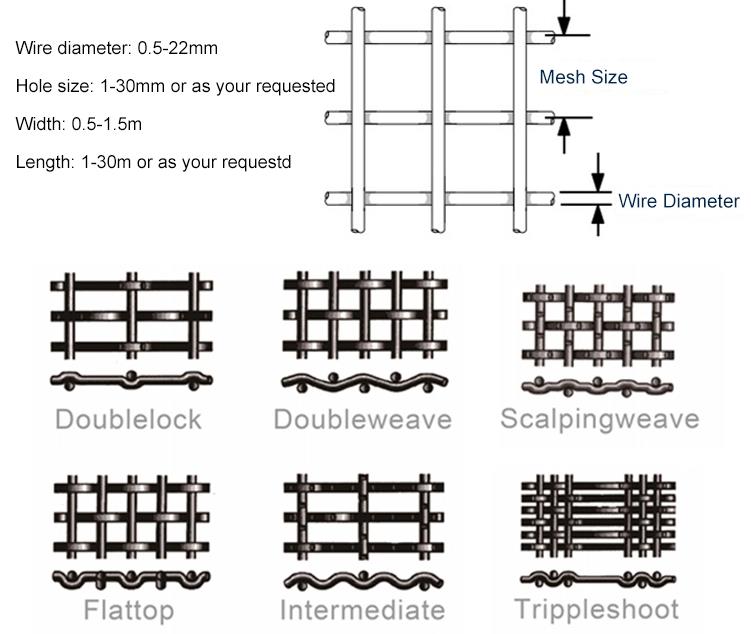

It has different weaving types and edge preparations. The main weaving types are flat top and crimped. Crimped type can be divided into single wire crimped and double wire crimped.

The high quality raw materials makes woven vibrating screen mesh have many features, such as high tensile, wear, temperature and weather resistance and so on.

With so many features, the woven vibrating screen mesh is used on vibrating machines in screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mining, quarry, aggregate production industries.

Woven wire vibrating screen is alsocalled quarry screen mesh or stonecrusher screen mesh. lt is made ofspring steel wire (high carbon steewire,medium carbon steel wire,manganese steel wire)and stainlesssteel wire. The high-quality raw ma-terials make woven vibrating screenmesh have many features, such ashigh tensile, wear, temperature andweather resistance and so on. Withso many features, the woven vibrat-ing screen mesh is used on vibratingmachines in screening and sizing allkinds of sand, gravel, coal, stone,rock and other materials in miningquarry,aggregate production industries.

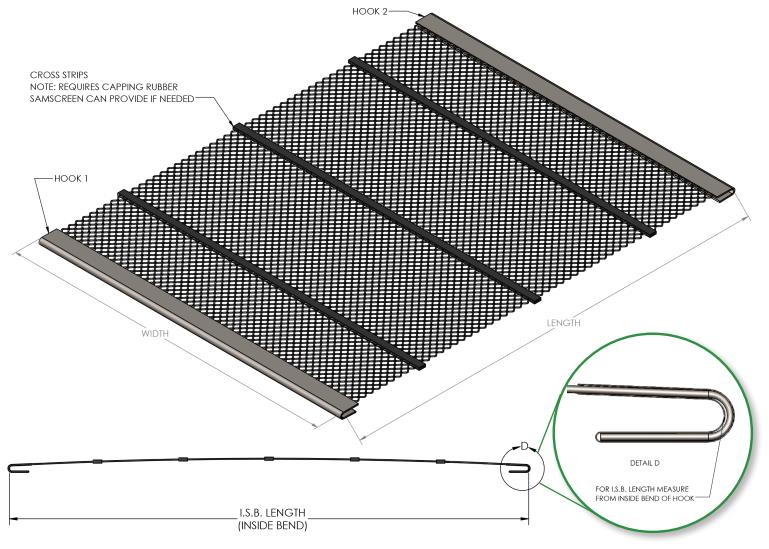

Specification

- Material: High tensile spring steel, manganese steel and stainless steel.

- Wire diameter: 0.71mm - 12.5mm.

- Opening size: 1mm - 100mm.

- Weaving type: Double crimped, intermediate crimped, flat top crimped, lock crimped.

- Mesh type: Square, rectangular slot, long slot.

- Surface treatment: Black or red color painted.

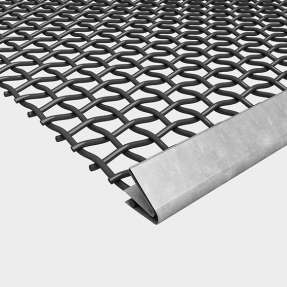

- Edge preparation: Plain, bent, reinforced shroud, welded shroud, bolt shroud.

- Hook type: C or U hook for 30° - 180°.

| Chemical sheet of the main material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel Grade | Chemical Composition (%) | ||||||||

| China (GB - YG) | USA (AISI) | C | Mn | Si | S | P | Cr | Cu | Ni |

| # 45 | 1045 | 0.42 - 0.50 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 50 | 1050 | 0.47 - 0.55 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 55 | 1055 | 0.52 - 0.60 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 60 | 1060 | 0.57 - 0.65 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| # 70 | 1070 | 0.67 - 0.75 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

| 65 Mn | 1566 | 0.62 - 0.70 | 0.50 - 0.80 | 0.17 - 0.37 | ≤ 0.035 | ≤ 0.035 | ≤ 0.25 | ≤ 0.25 | ≤ 0.30 |

Features

- Wear and abrasion resistant.

- Heavy impact resistant.

- High temperature resistant.

- Shock and pull resistant.

- High tensile strength and toughness.

- Acid, alkali and corrosion resistant.

- Long service life.

Applications

Woven vibrating screen mesh can be used as screen deck in quarry screen and crusher screen to separate and sort stone, sand, gravel, coal, rock and other materials. It is widely used in the large scale stone processing, asphalt mixing plants, coal, metallurgy, chemical and other industries.

Weave Styles

Plain Weave/ Double Crimp Woven Wire

The advantages of plain weave woven wire mesh are simplicity and high weave precision. This type of weave is used where the opening is relatively small, can guarantee achieving high efficiency and sustained performance screening.

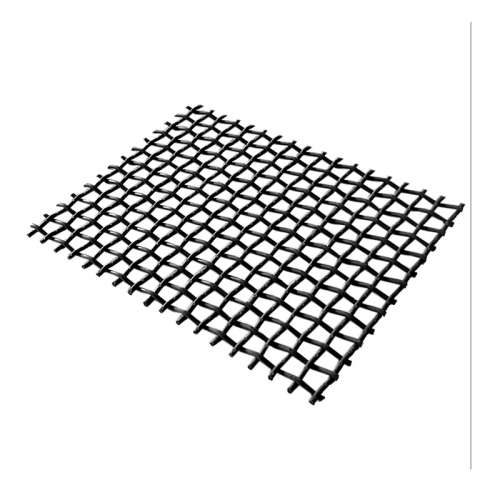

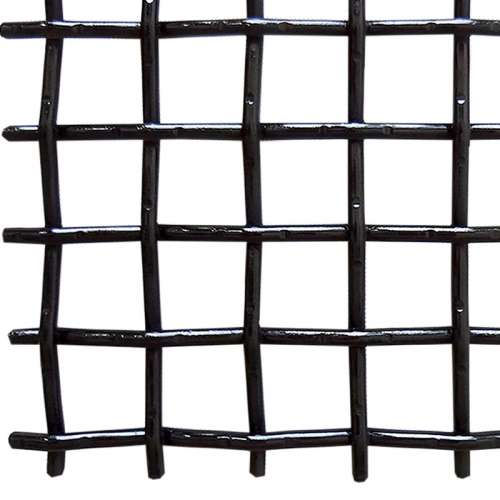

Lock Crimp Woven Wire

In the lock crimp weave type, weft and warp wires pass each other and get locked together at the point of intersection. The crimping is done to lock the wires to prevent from abrasion caused by wire movements. This weave type works perfectly for screening applications where the aperture size and wire diameter are relatively large.

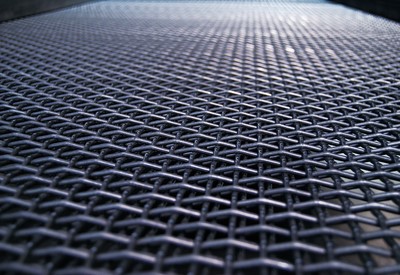

Flat Top Woven Wire

The flat top weave offers a smooth surface for easier material flow. This type of woven wire provides long abrasion resistance lifetime since there are no obstacles on the smooth surface side to strike the material during its flowing.

Intercrimp Woven Wire

Intermediate crimp, or simply intercrimp has extra crimps in warp and weft wires between the intersections, it is primarily used where larger aperture size is required while the wire diameter remains stable. The rigidity and stability are greater than common woven wire screen.

Thanks to its feature of large open area, the intercrimp woven wire screen is ideally suited for use in applications with high throughput.

Applications

Square wire mesh is mainly used as screens in various industries, such as mining, quarrying, screening plates, crushing screens, drum screens, vibrating screens, and screens used in road construction equipment or asphalt mixing equipment. And many more industries, including chemical, pharmaceutical, security and protection, construction, etc.