Square opening wire mesh is a most commonly used screening media by reason of its highly precise mesh apertures. Red Star’s woven wire screen is offered with the most precision mesh aperture within the global industry. Our square wire mesh features an aperture deviation of only ±3%, which is far superior to international standards of DIN47833 (Europe) and ASTM 2016-15 (North America).

We are able to deliver options of woven wire weave styles to perfectly suit your filtration and separation applications, such as plain weave (double crimp), lock crimp weave, flat top weave and intercrimp weave.

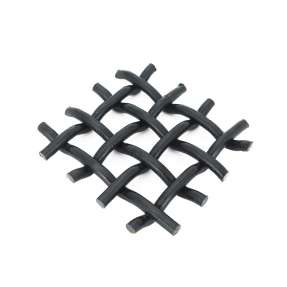

The flat top screen characteristics:

Smooth Surface: The surface of the flat top screen is smooth, with uniformly sized mesh openings, providing stable screening efficiency.

High Strength: Typically woven from metal wire or plastic wire, flat top screens exhibit high strength and durability, capable of withstanding significant screening pressure and vibration force.

Wear Resistance: Through special treatment, flat top screen materials have excellent wear resistance, maintaining stable screening performance over prolonged use.

Corrosion Resistance: Depending on the specific application, flat top screens can be made from different materials such as stainless steel, galvanized steel, or plastic, providing good corrosion resistance suitable for various working environments.

Strong Adaptability: Flat top screens are suitable for screening materials of various particle sizes and shapes, meeting the screening requirements of different fields and industries.

Easy to Clean and Maintain: With a smooth surface, flat top screens are easy to clean and maintain, ensuring good screening efficiency and cleanliness.

Customizability: Flat top screens can be customized in terms of specifications, materials, and mesh sizes according to customer requirements and specific application scenarios, meeting specific screening needs.

In summary, flat top screens exhibit characteristics such as smooth surface, high strength, wear resistance, corrosion resistance, strong adaptability, ease of cleaning and maintenance, and customizability. They are essential screening equipment widely used in the field of particle material screening.

The specification parameters of flat top screens

Material: Flat top screens can be made from various materials, including stainless steel, galvanized steel, nickel-chromium alloy steel, plastic, etc. The selection of material depends on the working environment and screening requirements.

Mesh Shape: The mesh shape of flat top screens can be square, rectangular, circular, etc., selected based on the characteristics and requirements of the screened material.

Mesh Size: Mesh size refers to the size of the mesh openings on the flat top screen, usually expressed in mesh size or mesh count. The appropriate mesh size is chosen based on the particle size of the screened material and screening requirements.

Screen Thickness: The thickness of flat top screens affects their load-bearing capacity and wear resistance, typically expressed in millimeters (e.g., 1mm, 2mm).

Screen Width and Length: The width and length of flat top screens are determined based on the specific screening equipment and usage requirements, usually expressed in meters or millimeters.

Frame Type: The frame of flat top screens can be wire frame, metal frame, plastic frame, etc., selected based on installation methods and usage requirements.

Surface Treatment: The surface of flat top screens can undergo special treatments such as galvanization, powder coating, etc., to enhance corrosion resistance and wear resistance.

Customization Requirements: Based on customer needs and specific application scenarios, flat top screens can be customized with different specification parameters to meet specific screening requirements.

In summary, the specification parameters of flat top screens include material, mesh shape, mesh size, screen thickness, screen width and length, frame type, surface treatment, etc. It is essential to select and customize these parameters according to specific screening requirements and usage scenarios.

Weave Styles

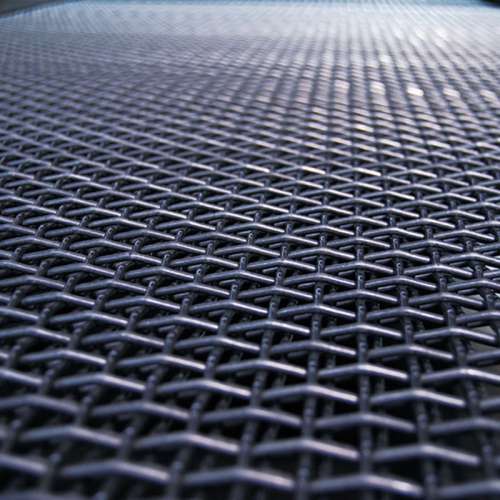

Plain Weave/ Double Crimp Woven Wire

The advantages of plain weave woven wire mesh are simplicity and high weave precision. This type of weave is used where the opening is relatively small, can guarantee achieving high efficiency and sustained performance screening.

Lock Crimp Woven Wire

In the lock crimp weave type, weft and warp wires pass each other and get locked together at the point of intersection. The crimping is done to lock the wires to prevent from abrasion caused by wire movements. This weave type works perfectly for screening applications where the aperture size and wire diameter are relatively large.

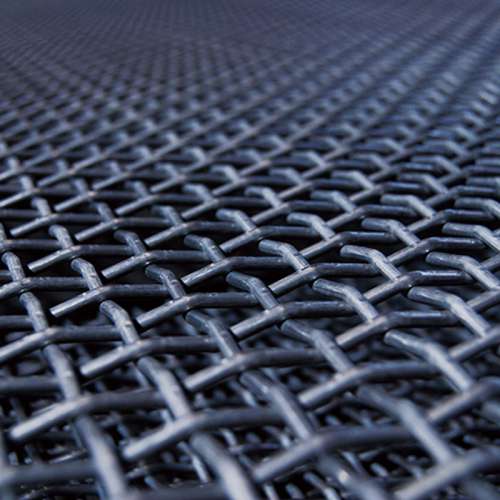

Flat Top Woven Wire

The flat top weave offers a smooth surface for easier material flow. This type of woven wire provides long abrasion resistance lifetime since there are no obstacles on the smooth surface side to strike the material during its flowing.

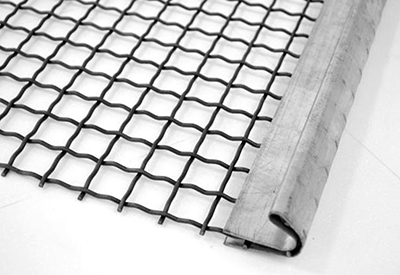

Intercrimp Woven Wire

Intermediate crimp, or simply intercrimp has extra crimps in warp and weft wires between the intersections, it is primarily used where larger aperture size is required while the wire diameter remains stable. The rigidity and stability are greater than common woven wire screen.

Thanks to its feature of large open area, the intercrimp woven wire screen is ideally suited for use in applications with high throughput.

Applications

Square wire mesh is mainly used as screens in various industries, such as mining, quarrying, screening plates, crushing screens, drum screens, vibrating screens, and screens used in road construction equipment or asphalt mixing equipment. And many more industries, including chemical, pharmaceutical, security and protection, construction, etc.