Known for its superior strength and durability, this mesh is ideal for heavy-duty applications, including vibrating screens in mining and quarrying industries, where robust material is essential.

In the production of high-quality square weave wire mesh, Red Star a professional woven wire mesh factory, has many years of experience. Our high-performance square woven mesh guarantee: accurate openings and wire sizes, superior flatness, top-quality materials, and high cost-effectiveness. We boast robust manufacturing capabilities and a substantial inventory, ensuring our square weave mesh meet the rigorous demands of your screening applications and industry standards.

Material Quality and Options: The mesh is available in two high-grade materials, High Tensile Spring Steel, known for its exceptional strength and flexibility, 65Manganese Steel, recognized for its high impact resistance and durability.

Wire Diameter Versatility: The wire diameter of this mesh ranges from a fine 1.22mm to a robust 12.7mm. This range allows for a wide spectrum of applications, from delicate screening to heavy-duty filtering.

Aperture Size for Precision Screening: Aperture sizes are varied, ranging from as small as 3.0mm to as large as 150.0mm. This diversity in aperture size makes the mesh suitable for a variety of screening tasks, from fine sand to larger rocks.

|

|

|

|

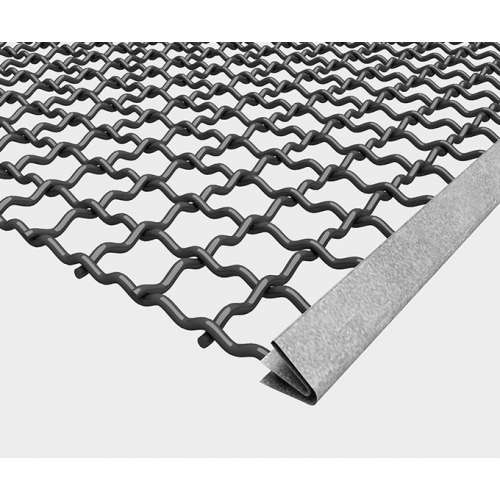

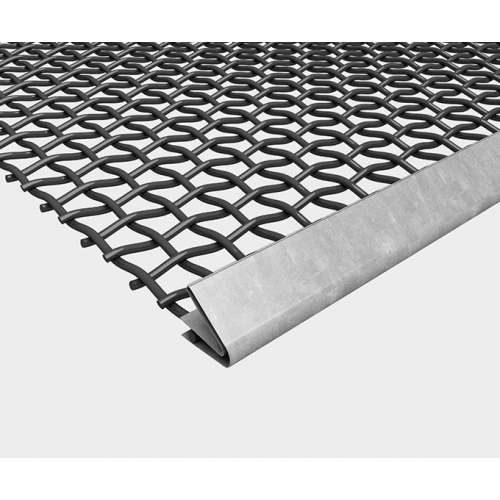

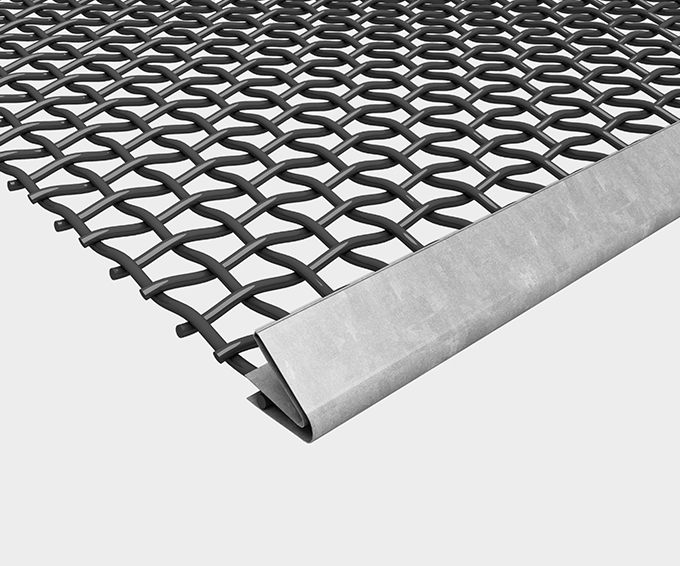

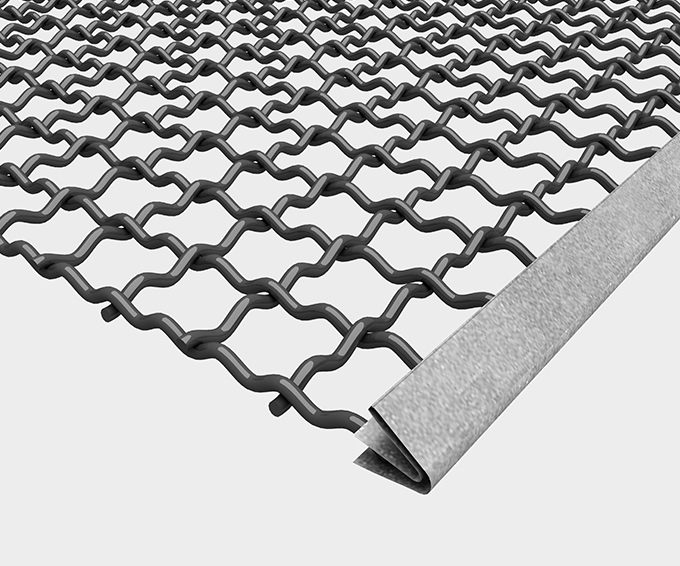

1. Plain Weave | 2. Inter Crimp | 3. Lock Crimp | 4. Flat Top |

1. Plain Weave

Structure: The simplest and most common weave, where the weft wire alternates over and under each warp wire.

Appearance: Creates a uniform, grid-like pattern with square openings.

Strength: Offers good mechanical stability and is durable.

Uses: Widely used for general-purpose screening, filtration, and protection in various industries like construction, agriculture, and food processing.

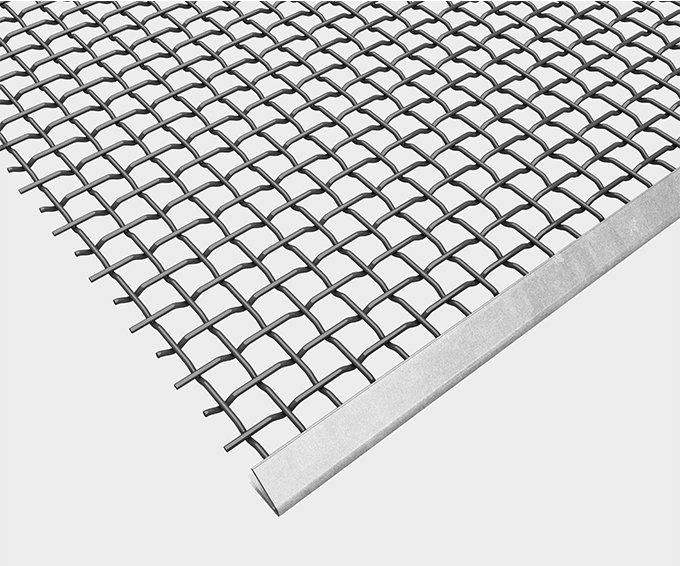

2. Inter Crimp

Structure: Both warp and weft wires are crimped before weaving, interlocking at each intersection.

Appearance: Produces a slightly more textured and rigid mesh compared to plain weave.

Strength: Enhances rigidity and prevents the mesh from distorting under heavy loads.

Uses: Suitable for heavy-duty applications where high strength and stability are required, such as in mining, quarrying, and industrial sieving

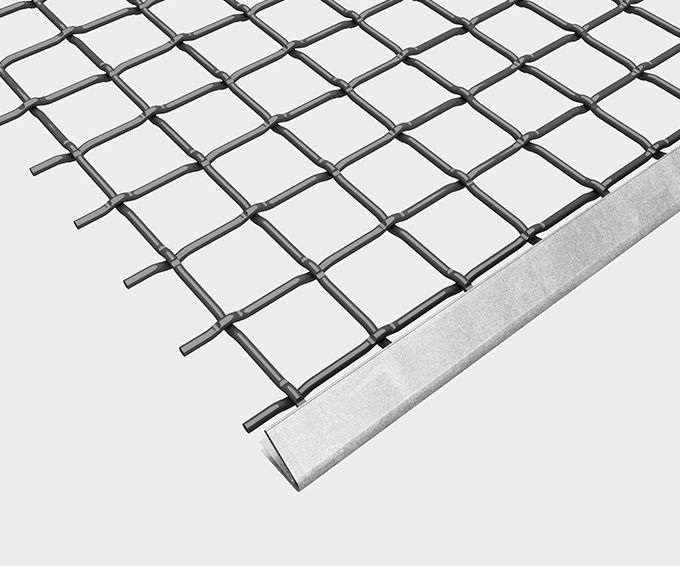

3. Lock Crimp

Structure: Wires are pre-crimped and locked in place at the points of intersection, ensuring consistent spacing and rigidity.

Appearance: Features a very precise and tight mesh structure with distinct crimped junctions.

Strength: Offers exceptional dimensional stability and strength due to the locking mechanism.

Uses: Ideal for applications requiring accurate sizing and high load-bearing capacity, such as architectural design, safety grilles, and fencing.

4. Flat Top

Structure: The weft wires are crimped, while the warp wires remain flat on the surface.

Appearance: Provides a smooth top surface on one side, reducing wear and friction.

Strength: Combines the strength of a crimped weave with a smooth top surface, making it durable and easy to clean.

Uses: Often used in applications where a smooth surface is necessary, like in food processing, drying racks, and conveyor belts.

Features of High Tensile Steel Screen Mesh:

Robust Construction: Exhibits exceptional strength and load-bearing capacity, ideal for heavy-duty applications.

Enhanced Durability: Offers excellent resistance to corrosion, including against acids and alkalis, ensuring longevity.

Versatile Performance: Adapts well to extreme temperatures, both high and low, maintaining performance integrity.

Efficient Screening: Designed to prevent blinding and plugging, enhancing screening efficiency.

Ease of Use: Simple to install and requires minimal maintenance, reducing downtime.

Variety of Screen Types: Available in multiple vibrating screen mesh types to suit different screening needs.

Specification of High Tensile Steel Screen Mesh:

| Item No. | Opening (mm) | Wire Size (mm) | Weight kg/㎡ |

| 1 | 3 | 2 | 10.16 |

| 2 | 3.15 | 1.4 | 5.47 |

| 3 | 3.15 | 2 | 9.86 |

| 4 | 3.18 | 1.22 | 4.3 |

| 5 | 3.18 | 1.37 | 5.24 |

| 6 | 3.18 | 1.83 | 8.49 |

| 7 | 3.18 | 2.03 | 10.05 |

| 8 | 3.18 | 2.34 | 12.6 |

| 9 | 3.18 | 2.67 | 15.48 |

| 10 | 3.35 | 2 | 9.5 |

| 11 | 3.75 | 2 | 8.83 |

| 12 | 3.75 | 2.5 | 12.7 |

| 13 | 3.97 | 3.05 | 16.83 |

| 14 | 4 | 2 | 8.47 |

| 15 | 4 | 2.5 | 12.21 |

| 16 | 4 | 3.15 | 17.62 |

| 17 | 4.35 | 2 | 8 |

| 18 | 4.5 | 2.5 | 11.34 |

| 19 | 4.5 | 2.8 | 13.64 |

| 20 | 4.5 | 3.15 | 16.47 |

| 21 | 4.75 | 2 | 7.53 |

| 22 | 4.75 | 2.8 | 13.19 |

| 23 | 4.75 | 3.15 | 15.95 |

| 24 | 4.76 | 2.03 | 7.71 |

| 25 | 4.76 | 2.34 | 9.79 |

| 26 | 4.76 | 2.67 | 12.19 |

| 27 | 4.76 | 3.05 | 15.13 |

| 28 | 4.76 | 3.43 | 18.24 |

| 29 | 5 | 1.6 | 4.93 |

| 30 | 5 | 2 | 7.26 |

| 31 | 5 | 2.5 | 10.58 |

| 32 | 5 | 2.8 | 12.77 |

| 33 | 5 | 3.15 | 15.46 |

| 34 | 5.3 | 2.5 | 10.18 |

| 35 | 5.3 | 3.15 | 14.91 |

| 36 | 5.56 | 2.67 | 11 |

| 37 | 5.56 | 3.05 | 13.72 |

| 38 | 5.6 | 2.8 | 11.85 |

| 39 | 5.6 | 3.15 | 14.4 |

| 40 | 6 | 2 | 6.35 |

| 41 | 6 | 2.5 | 9.34 |

| 42 | 6 | 3.15 | 13.77 |

| 43 | 6.3 | 2 | 6.12 |

| 44 | 6.3 | 2.5 | 9.02 |

| 45 | 6.3 | 3.15 | 13.34 |

| 46 | 6.3 | 4 | 19.73 |

| 47 | 6.35 | 2.34 | 8 |

| 48 | 6.35 | 2.67 | 10.04 |

| 49 | 6.35 | 3.05 | 12.57 |

| 50 | 6.35 | 3.43 | 15.28 |