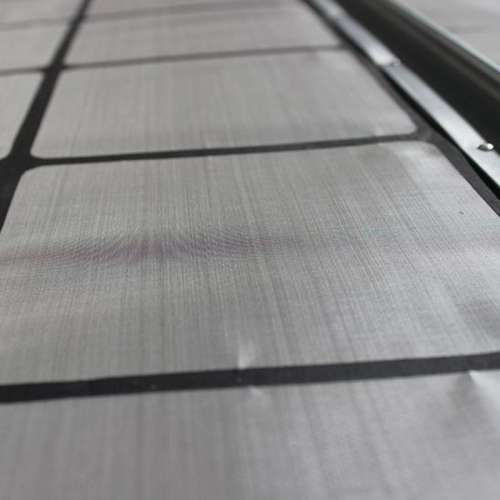

The shale shaker screen is a mesh screen that is created out of woven metal that goes inside the shale shaker. Whenever solids or cuttings are produced from drilling equipment, they are coated in drilling liquid. When those cuttings are shaken over shale shaker screens, the screen is able to capture all of the solid particles and allow any excess mud to drip through the screen where it can then be deposited back into the tank.

There are many different types of shale shaker screens available on the market today, each with different types of weaving to create the screen and different sizes of mesh. Ultimately choosing the best screen comes down to choosing the finest mesh you possibly can that doesn’t result in drilling liquid being lost from the front of the shaker screen that match the type of shaker equipment you are using.

Red Star stainless steel screen mesh is a type of replacement screens for the majority of shale shakers. Our available materials include 304, 316 and 316L stainless steel.

Specifications

Materials available

304, 316 and 316L stainless steel

Opening size

>0.015mm

Screen size

Max.2.5m width

Applications

- Oil, chemical and food processing;

- Wire mesh filter manufacturing;

- Sorting and screening of solid, liquid and gas in mine, metallurgy, airspace, etc.

- Machine production;

- Screening of sand, rock, coal, gavel, metal materials;

- Quarry, aggregate, mining industries;

- Road construction;

- Asphalt mixing plant;

Gallery