The self-cleaning harp wire screen has the maximum open area in all Anpeng self-cleaning screen mesh series. Like the traditional harp screen mesh or piano wire screen, the self-cleaning harp screen is best for desanding or removing fines while maintaining material in size. It is most efficient in dry screening of sand, gravel, loam, topsoil, mulch, compost, golf sand and more.

Red Star’ piano wire screen delivers largest screening area for rapid removal of fines. In contrast to conventional harp screen or piano wire screen, this self-cleaning screen features longer service life while enabling the specifications of material remaining unchanged. Piano wire screens are ideal for screening sand, compost and topsoil.

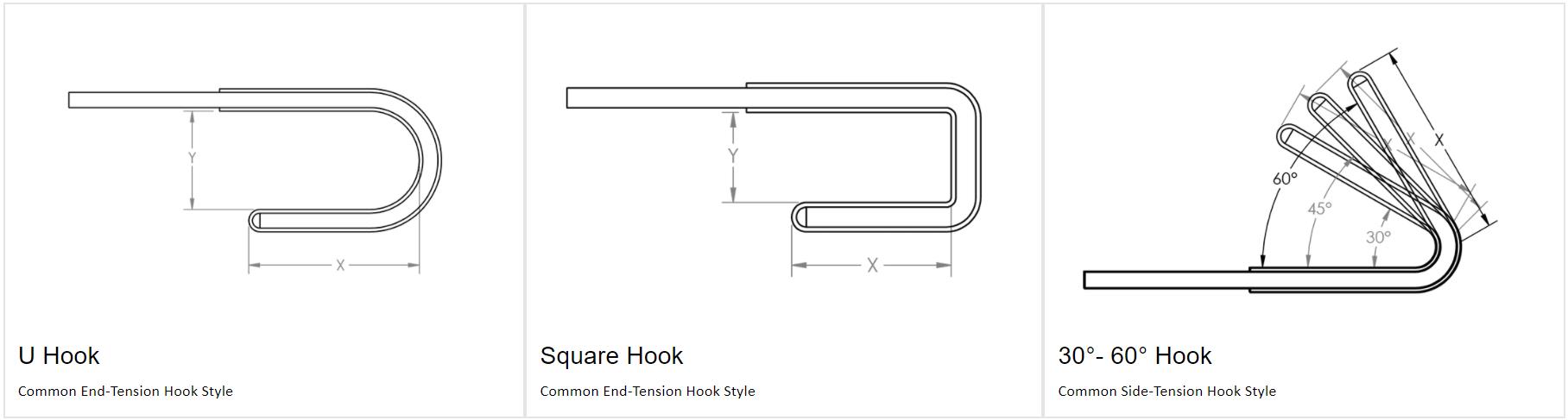

The hooks shown below are examples of common types, however, the hook shape, as well as the backleg and throat dimensions, can be customized for any machine.

Opening & Wire Sizes

| Opening Size | Standard Wire | Heavy Wire | Heavy Duty Wire |

|---|---|---|---|

| 1.2mm (3/64″) | .50mm (.020″) | .65mm (.026″) | |

| 1.5mm (1/16″) | .65mm (.026″) | .80mm (.031″)* | |

| 2mm (3/32″) | .65mm (.026″) | .80mm (.031″)* | |

| 3mm (1/8″) | .80mm (.031″)* | 1.0mm (.039″) | |

| 4mm (5/32″) | 1.0mm (.039″) | 1.2mm (.047″) | |

| 5mm (3/16″) | 1.0mm (.039″) | 1.2mm (.047″) | |

| 6mm (1/4″) | 1.2mm (.047″) | 1.4mm (.055″) | 2.0mm (.079″) |

| 8mm (5/16″) | 1.4mm (.055″) | 1.6mm (.063″) | 2.0mm (.079″) |

| 10mm (3/8″) | 1.4mm (.055″) | 1.6mm (.063″) | 2.0mm (.079″) |

| 12mm (1/2”) | 1.6mm (.063″) | 1.8mm (.070″)* | 2.0mm (.079″) |

| 16mm (5/8″) | 2.0mm (.079″) | 2.5mm (.098″) | 3.0mm (.118″) |

| 19mm (3/4″) | 2.0mm (.079″) | 2.5mm (.098″) | 3.0mm (.118″) |

Applications

- Sand and gravel industry

- Ore preparation plants

- Mining industry

- For wet, sticky, hard-to-screen materials