Triangle Opening Self-cleaning Screen, is like the diamond opening screen, with an extra straight wire in between every crimped wire which forms the triangle openings on the screen. It is designed to replace traditional fine mesh to better reduce blinding. The structure of triangle mesh wire fabric also reinforces the screen for high impact and heavy load screening.

Unlike conventional tensioned wire mesh that requires more machine downtime due to replacement of screens, the modular design of the self-cleaning screen helps significantly and efficiently boosting productivity while reducing machine downtime. Red Star can offer several installation methods to accommodate customer’s individual demands. Opening sizes are available in a range of 2.03-152.4mm.

- Resistant to abrasion;

- Light weight, small noise, high screening effectiveness, cost-effectiveness, environmental friendliness;

- Feature excellent dewatering capacity;

- Applicable for separating water from mud on the surface of tunnel boring machine;

- Applicable for filtering water from mud during the tunneling;

- Industries served: mining, sand and gravel industry;

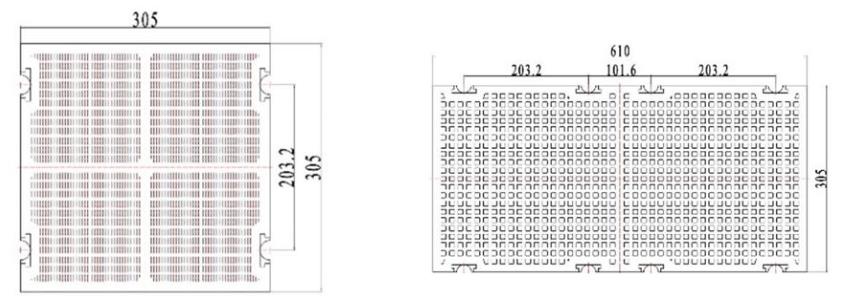

(Regular size: 305*305, 305*610; Other sizes are customizable)

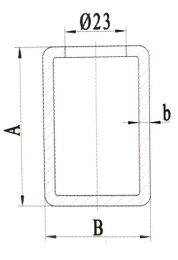

Specifications of Support Frames

| Model(S/N) | A(mm) | B(mm) | b(mm) |

| 1 | 90 | 50 | ≥4 | |

| 2 | 80 | 40 | ≥4 | |

| 3 | 40 | 40 | ≥4 |

- Sand and gravel industry

- Ore preparation plants

- Mining industry

- For wet, sticky, hard-to-screen materials