Red Star polyurethane meshes are manufactured by an open cast iron process, their useful life is 1.5 to 2 times longer than that of injection polyurethane meshes. Although the outdoor production method requires more labor, it has upper useful life -resistant life and a lower maintenance cost, this is mainly due to the long and slow curing process that improves the reticulation of the molecules of polyurethane. Applications Polyurethane meshes allow effective screening in most dry and humid applications. All raw materials and manufacturing equipment of Polyurethane meshes of Red Star are from Europe. Our quality control has passed the ISO quality management system certification, which allows us to offer polyurethane meshes of excellent quality.

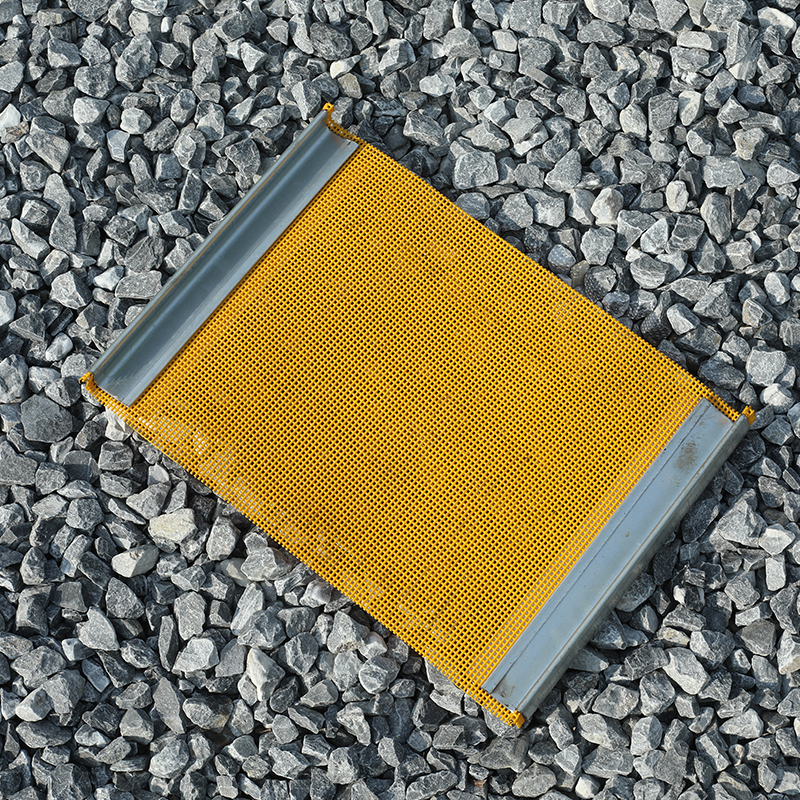

PU Edged Sieving Plate Polyurethane Dewatering Screen Mesh PU Screening Panel

Polyurethane sieve plate has the characteristics of good wear resistance, long service life, high screening quality

Polyurethane Fine Screen

Red Star’s polyurethane fine screens are applicable to Derrick’s screening machines for replacement of Derrick wi

Tufflex Screen

TPU hot melt screen mesh is a new type of screening material commonly used in vibrating screens, circular vibrat

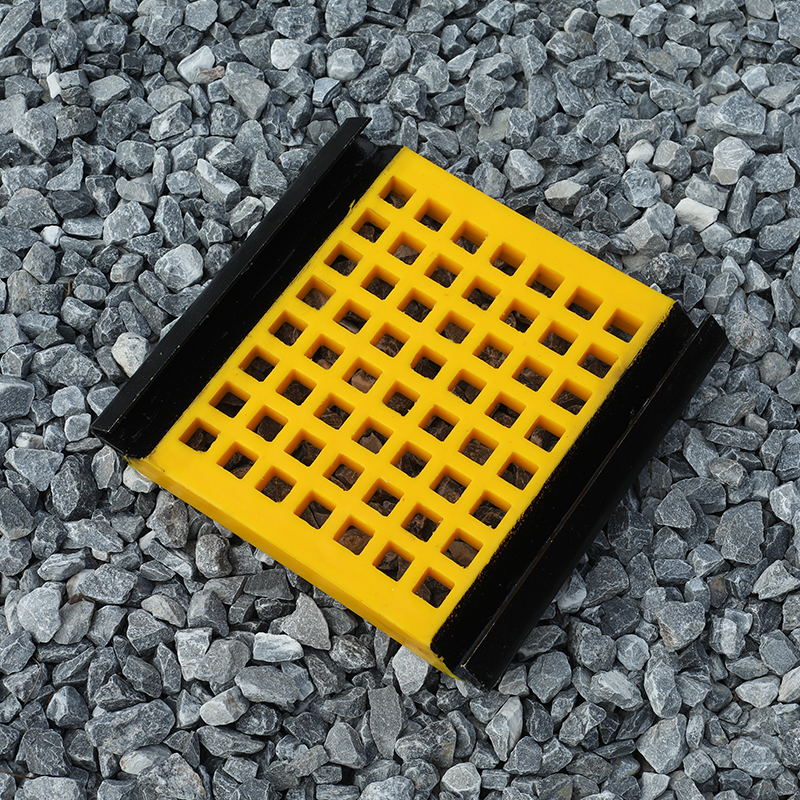

Flip Flow Screen

Flip flow screen or flip flop screen is a type of PU screening media suited to efficiently screen dry, sticky,

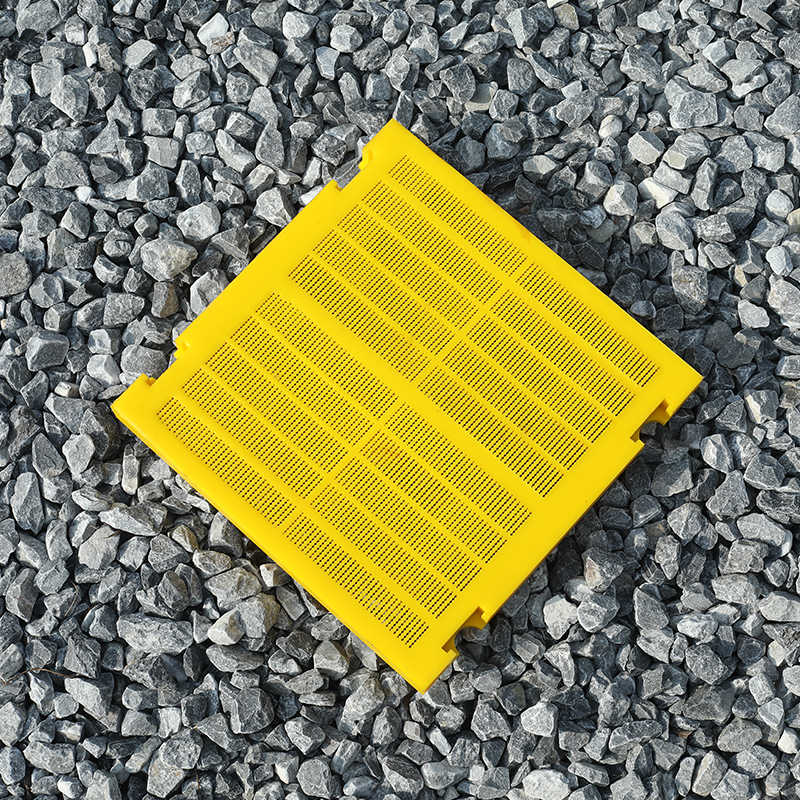

Polyurethane Screen Panel

Red Star manufactures polyurethane screen panel available with solutions tailored to customer’s application needs i

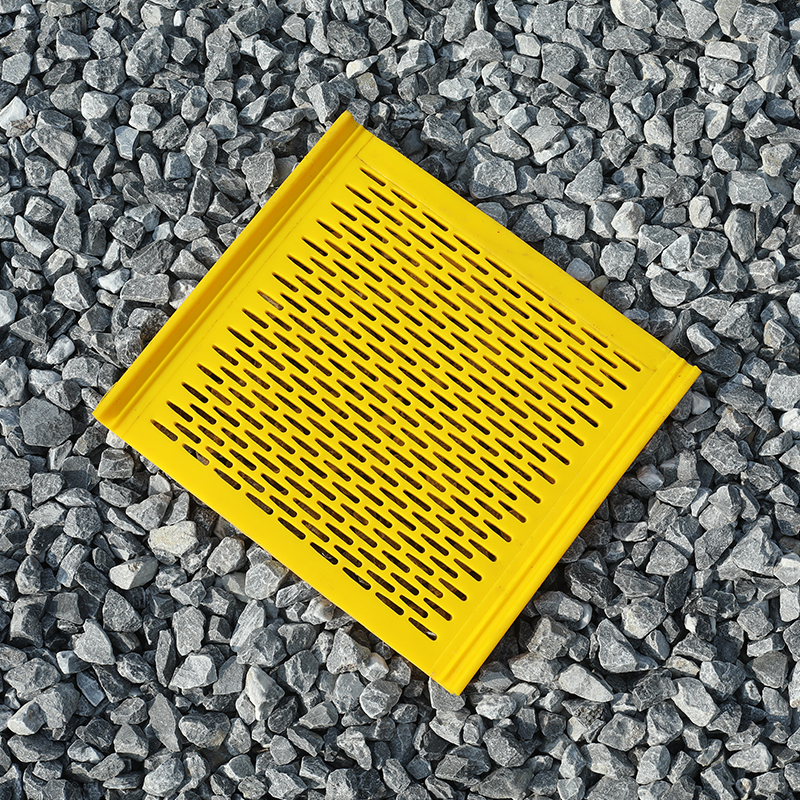

Polyurethane Tensioned Screen

Polyurethane tensioned screen is an optimal alternative to woven wire screens The assembly of polyurethane tension