How to improve the screening efficiency of woven mine screens

For woven mine screens with high screening efficiency, high-grade materials, advanced weaving technology, and excellent woven mine screen weaving machines are the three major factors for producing high-standard woven mine screens.

For woven mine screens with high screening efficiency, high-grade materials, advanced weaving technology, and excellent woven mine screen weaving machines are the three major factors for producing high-standard woven mine screens.

These three factors determine the service life, screening efficiency, and material screening quality of the woven mine screen. Therefore, woven mine screens with high screening efficiency must use advanced processing methods and high-standard manganese steel. So what are the requirements for screening for high-performance manganese steel screens?

First of all, the three elements of high screening efficiency conditions: vibration speed, feed volume, and high-standard manganese steel screens.

Regular and certain amplitude vibration is the prerequisite for screening. Therefore, before and during the screening operation, the motor and vibration machinery should be checked in time. The lubricating oil should be added where it should be added, or the semi-automatic filling machine that automatically fills the lubricating oil should be checked to see if it works on time and whether the motor is running normally.

Feeding is generally done with a conveyor belt. The conveyor belt conveying process is long and is easily neglected. The rollers often fail. Due to the long conveyor belt, it is inevitable that the failure cannot be found.

In addition, due to the failure of the rollers, the conveyor belt transportation will be blocked, or the uneven force on both sides of the conveyor belt will cause the material to be transported sideways, which will cause the material to enter the feed port at an uneven feeding speed, causing the manganese steel screen surface to be unevenly stressed, and may also cause blockage.

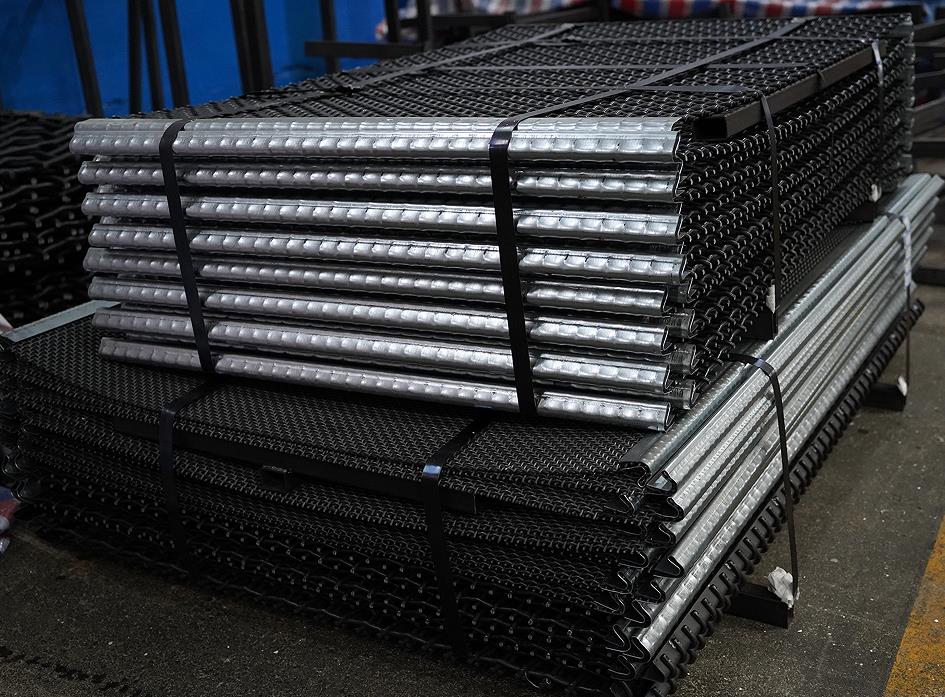

Then there is the excellent woven mine screen. Because the selected mine screen material is wear-resistant, the mesh is uniform, and the mesh surface is flat, it can greatly improve the screening efficiency.