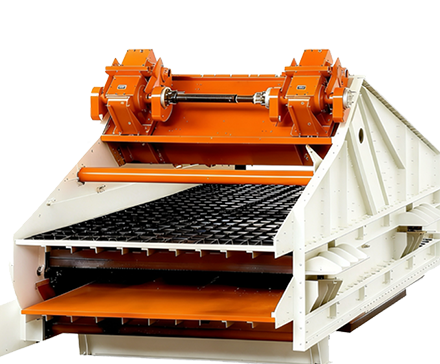

Maintenance of Self-Cleaning Screen Mesh Materials for Mining

Proper maintenance of self-cleaning screen mesh materials is essential for

maximizing efficiency and prolonging the lifespan of your mining equipment. In

industries like mining, where heavy-duty screening is crucial, regular upkeep

can reduce downtime, prevent costly repairs, and ensure optimal performance.

Why Maintenance Matters

Self-cleaning screen meshes are designed to reduce clogging and improve

material flow. However, regular wear and tear from abrasive materials can affect

performance if not maintained properly. Routine maintenance helps preserve the

mesh’s self-cleaning properties and enhances its durability, ensuring continued

efficiency.

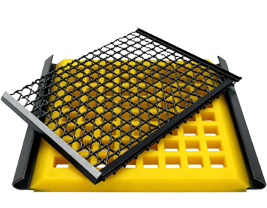

Key Maintenance Tips

Regular Inspections

Perform routine visual inspections to check for damage or excessive wear.

Look for signs of fraying, tears, or bent wires, especially in high-impact

areas. Identifying issues early can prevent more significant damage.

Cleaning

Even though these meshes are self-cleaning, debris or fine particles can

sometimes build up. Clean the screen regularly with water or air to remove any

persistent blockages and to maintain its performance.

Lubrication of Moving Parts

While the mesh itself may not require lubrication, the supporting frame and

tensioning mechanisms do. Ensure all moving parts are well-lubricated to avoid

strain and extend the lifespan of both the mesh and the screen system.

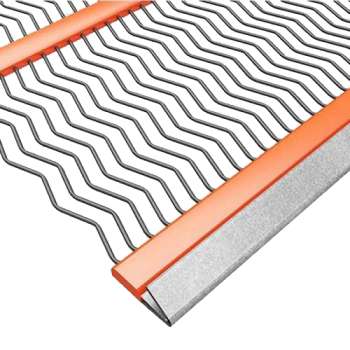

Tension Adjustment

Maintaining proper tension is crucial. A screen that’s too tight may break

under stress, while a loose screen can sag, reducing efficiency. Regularly check

and adjust the tension to maintain optimal performance.

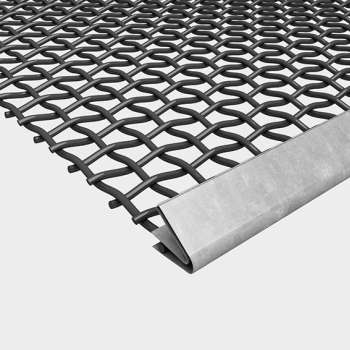

Replace Worn Meshes

Over time, even the best self-cleaning meshes will wear out. Monitor the

condition of the screen regularly, and replace any worn sections to maintain

productivity.

Benefits of Regular Maintenance

Extended Lifespan: Proper care extends the life of your screen mesh

materials, saving on replacement costs.

Increased Efficiency: Well-maintained screens ensure optimal material flow,

reducing clogging and downtime.

Reduced Downtime: Catching small issues early prevents larger, more expensive

repairs and minimizes operational interruptions.

Conclusion

Maintaining self-cleaning screen mesh materials is critical for mining

operations that rely on consistent, high-performance screening. By conducting

regular inspections, cleaning, and replacing worn parts, you can keep your

equipment running smoothly and avoid costly delays. Proper maintenance will not

only enhance productivity but also improve the lifespan of your screen meshes,

providing long-term cost savings.

Leave A Reply

By using form u agree with the message sorage, you can contact us directly now