How to Choose the Right Polyurethane Vibrating Screen Mesh for Your Application

Selecting the appropriate Polyurethane Vibrating Screen Mesh is essential for industries like mining, aggregates, and recycling that require durable and efficient screening solutions

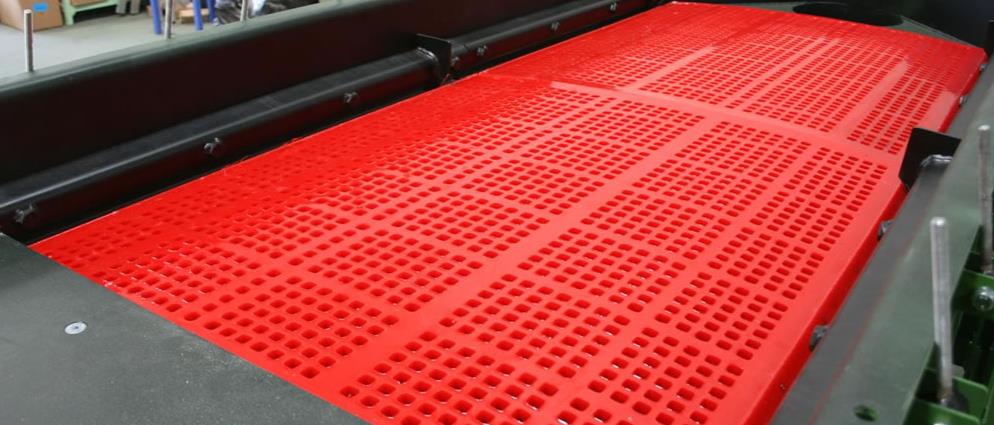

Selecting the appropriate Polyurethane Vibrating Screen Mesh is essential for industries like mining, aggregates, and recycling that require durable and efficient screening solutions. Here are the key factors to consider when choosing the right mesh for your specific needs:

1. Material Quality and Durability

Choose high-quality polyurethane mesh to ensure strong wear and abrasion resistance, as this will extend the mesh’s lifespan and reduce maintenance costs. Superior polyurethane materials withstand heavy loads and abrasive conditions, making them ideal for high-impact environments where other materials might wear down quickly.

2. Aperture Size and Shape

The aperture size and shape are critical for accurate particle separation. Smaller apertures are suitable for finer materials, while larger ones allow for greater material flow and are better for coarse materials. Choosing the right aperture size and shape improves screening efficiency and minimizes the risk of clogging.

3. Thickness and Flexibility

Polyurethane vibrating screen meshes come in various thicknesses, and the right choice depends on the nature of the material being screened. Thicker meshes provide added strength for heavy-duty applications, while thinner, more flexible meshes are ideal for sticky or wet materials. Flexibility in the mesh design also helps prevent blinding and ensures consistent performance over time.

4. Compatibility with Screening Equipment

Ensure that the polyurethane mesh is compatible with your existing screening equipment. Accurate sizing is essential to avoid gaps and ensure a secure fit, maximizing both safety and efficiency. Some polyurethane meshes are customizable to meet specific equipment requirements, so verify measurements before purchase.

5. Maintenance and Replacement

Opt for polyurethane meshes that are easy to install and replace. Modular designs are especially helpful for quick changes, reducing downtime and keeping operations running smoothly. Polyurethane’s low maintenance needs make it a cost-effective solution over time.

In conclusion, choosing the right polyurethane vibrating screen mesh involves assessing material quality, aperture size, thickness, compatibility, and maintenance requirements. By selecting the mesh that best suits your needs, you can improve efficiency, reduce downtime, and increase productivity across your screening applications.