How to quickly identify the quality of polyurethane screens for mining?

To judge the quality of polyurethane screens for mining, we need to consider aspects such as appearance quality, opening rate and aperture ratio

To judge the quality of polyurethane screens for mining, we need to consider aspects such as appearance quality, opening rate and aperture ratio, connection method, mechanical properties, chemical resistance and thermal stability. The appearance quality of polyurethane mining screens should be flat, pure in color and intact, and the opening rate and aperture ratio should meet actual needs. The connection method of polyurethane screens should be tight, reliable and easy to disassemble. Mechanical properties need to have strong tensile strength and moderate elongation at break, and the hardness should be selected according to the use environment. Chemical resistance and thermal stability should be good. It is recommended to choose products produced by regular manufacturers and consult professionals to ensure that you buy reliable polyurethane screens.

The quality of polyurethane screens can be judged from the following aspects:

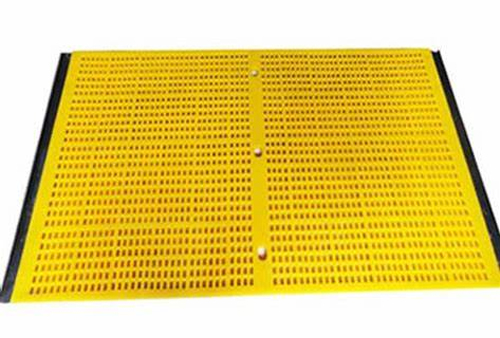

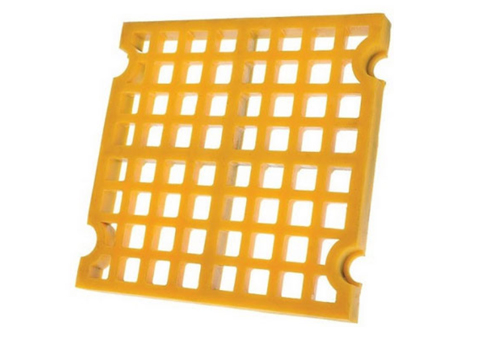

1. Appearance inspection of polyurethane screens for mining

(1). Surface flatness: The surface of a good quality polyurethane screen should be flat and smooth, without obvious unevenness, bubbles, impurities or lumps. If the surface is uneven, it may affect the flow of materials on the screen, resulting in reduced screening efficiency and easy to cause material accumulation and blockage.

(2). Color uniformity: High-quality polyurethane screens have uniform color, without color difference, color spots or discoloration. Uneven color may indicate uneven material mixing or the influence of adverse factors during the production process, such as improper temperature control or unstable raw material quality.

(3). Edge treatment: Carefully observe the edge of the screen. The edge of a good quality screen should be finely processed, smooth and free of burrs, flash or cracks. Good edge treatment can not only ensure that the screen can fit the equipment tightly during installation to prevent material leakage, but also improve the overall stability and safety of the screen.

2. Performance testing of mining polyurethane screen materials

(1). Hardness test: A hardness tester can be used to test the hardness of the polyurethane screen. Appropriate hardness can ensure that the screen will not be easily deformed or damaged when subjected to material impact and friction. Too high hardness may cause the screen to become more brittle and easy to break; too low hardness may make the screen poor in wear resistance and prone to wear. Generally speaking, the hardness of polyurethane screens used in mines should be between Shore A70 and 90.

(2). Elasticity test: Preliminary judgment of its elasticity by pressing or stretching the screen. A good quality polyurethane screen has good elastic recovery ability. After being subjected to a certain degree of external force, it can quickly return to its original state without leaving obvious deformation marks. Good elasticity can make the screen better adapt to the impact of materials during work, reduce fatigue damage, and extend service life.

(3). Wear resistance evaluation: Although direct evaluation of wear resistance requires professional equipment and a long time, a preliminary judgment can be made by observing the material and surface treatment of the screen. High-quality polyurethane materials themselves have good wear resistance. At the same time, some screens may undergo special surface treatment to further improve wear resistance, such as adding wear-resistant coatings. In addition, you can also refer to the wear resistance data provided by the manufacturer or other user feedback.

3. Quality inspection of mesh size of polyurethane screens for mining

(1). Mesh accuracy: Use tools such as calipers or microscopes to measure the mesh size of the screen and check whether it meets the nominal specifications. The accuracy of the mesh size is crucial to the screening effect. Meshes with high accuracy can ensure accurate particle size classification of materials. The mesh size error of high-quality polyurethane screens should be controlled within a small range. For example, for some screens with high accuracy requirements, the mesh size error may not exceed ±0.1mm.

(2). Mesh uniformity: Observe whether the mesh distribution of the screen is uniform and whether the shape is regular. Uniform mesh distribution and regular shape can ensure that the material passes through the mesh evenly on the screen surface, avoiding excessive or insufficient local screening. If the mesh size is different or unevenly distributed, it will seriously affect the screening accuracy and efficiency.

(3). Opening rate: The opening rate refers to the ratio of the total area of the screen mesh to the entire screen surface area. The appropriate opening rate can improve the screening efficiency while ensuring the strength of the screen. The opening rates of polyurethane screens for different purposes are different, and the opening rate can be judged according to the specific screening needs. Generally speaking, the opening rate of the screen used for coarse screening is relatively high, while the opening rate of the screen used for fine screening is relatively low.

4. Structural strength test of polyurethane screen for mining

(1). Tensile strength: The tensile strength of the screen is tested by tensile test. A good quality polyurethane screen should have sufficient tensile strength to withstand the tension of the material during the screening process without breaking. You can refer to the tensile strength index in the product manual or relevant standards for judgment.

(2). Impact strength: Simulate the impact of the material on the screen and observe the impact resistance of the screen. This can be preliminarily evaluated by a simple drop impact test, that is, an object of a certain weight falls on the screen from a certain height to observe whether the screen is damaged or deformed. High-quality polyurethane screens should be able to withstand a certain degree of impact without damage to ensure normal use in harsh environments such as mines.

5. Verification of corrosion resistance of polyurethane screens for mining

(1). Chemical reagent resistance test: If there are chemical corrosive substances in the mining environment, a small amount of relevant chemical reagents can be dripped on the screen sample to observe whether it changes color, softens, expands or other chemical reactions occur. High-quality polyurethane screens should have good corrosion resistance and be able to resist the erosion of common chemicals in mines, such as acidic or alkaline slurry.

(2). Moisture resistance: Place the screen in a humid environment for a period of time, such as in a high-humidity test chamber for several days, and then check its performance changes. Good quality polyurethane screens should be able to maintain their stable performance in a humid environment, and will not become moldy, deformed or lose strength due to moisture.

6. Production process and quality certification of polyurethane screens for mining

(1). Production process details: Understand the manufacturer's production process, such as whether high-precision molds and advanced casting molding technology are used. Advanced production processes can ensure the quality stability and consistency of the screen. For example, high-precision molds can ensure that the mesh size is accurate and the shape is regular, while good casting molding technology can make the internal structure of the screen dense and defect-free.

(2). Quality certification: Check whether the screen has passed relevant quality certifications, such as ISO quality management system certification, industry standard certification, etc. These certifications are a recognition of the manufacturer's production capacity and product quality, and can be used as an important reference for judging the quality of the screen.

Judging the quality of polyurethane screens for mining requires comprehensive consideration of appearance quality, opening rate and aperture ratio, connection method, mechanical properties, chemical resistance and thermal stability. When purchasing, it is recommended to choose products produced by regular manufacturers and consult professionals to ensure that you purchase a polyurethane screen of reliable quality.