How to prevent the polyurethane screen plate from breaking too quickly?

Polyurethane screen plates will begin to have a series of problems if they are not maintained in time during long-term use, and breaking too quickly is also one of the faults

Polyurethane screen plates will begin to have a series of problems if they are not maintained in time during long-term use, and breaking too quickly is also one of the faults. This phenomenon should be considered whether it is due to its own quality problems or other important reasons. Let's study and analyze it below:

1. Self-factors include: insufficient tension of the polyurethane screen plate, which causes the polyurethane screen plate to vibrate, usually along the edge or side strip of the polyurethane screen plate. Check the tension of the polyurethane screen plate frequently to check whether the polyurethane screen plate can be installed firmly.

2. Material conveying problem. Since the vibrating screen is in the process of continuous feeding, if the feeding is too much, it hinders the normal movement of the material on the screen surface, which is not only easy to make the polyurethane screen plate fatigue loose, but also greatly reduces the material processing capacity.

3. Giving a large amount of material at one time will cause the company's own development to be in an unbalanced operation. The motor workload suddenly increases, which is not only easy to damage the polyurethane screen plate, but also more likely to cause damage to the vibration motor, so the material should be fed evenly when feeding.

4. Under the feeding mode with strong impact force, the polyurethane screen in the vibrating screen needs to add a buffer hopper. The material that directly hits the polyurethane screen plate will consume the exciting force generated by the vibration source, which is more likely to cause damage to the polyurethane screen and fatigue of the screen.

5. The quality management problem of the polyurethane screen plate is an important factor that causes the polyurethane screen plate to break too quickly. If the material quality of the polyurethane screen cannot meet the screening requirements of the material, the polyurethane screen will be damaged quickly.

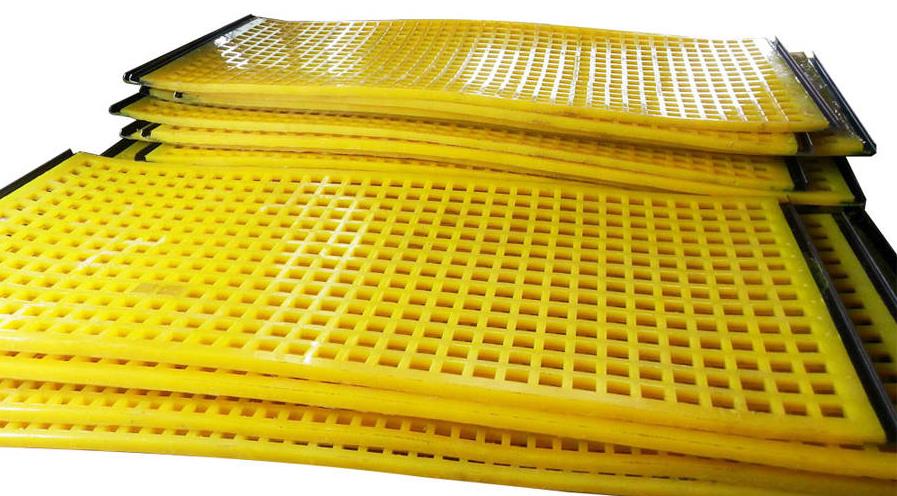

When choosing a polyurethane composite screen plate, you should look at its appearance, whether it can pass through exquisite, whether the screen can be flat, whether the color of the polyurethane screen plate is simple, whether there are broken strips, burrs, lack of material, mixed materials, tight seams and other phenomena, a good appearance is the premise to ensure its usable network life.