Four o'clock to clear the advantages of the screening of polyurethane edge mines.

In the mining and industrial production process, screening is a crucial link, which directly affects the efficiency and quality of material classification

In the mining and industrial production process, screening is a crucial link, which directly affects the efficiency and quality of material classification. In order to achieve this purpose, polyurethane-edged mine screens have become an indispensable tool. This polyurethane mine screen is highly preferred for its excellent performance and wide range of applications. Next, we will discuss the characteristics, advantages and applications of this material in detail from a professional perspective.

1. We need to understand what polyurethane is

Polyurethane (PU) is a high molecular polymer formed by the reaction of polyol and isocyanate. It has excellent wear resistance, elasticity and chemical resistance. When used as an edge wrap for mine screens, it provides additional protection and enhances the overall durability and service life of the screen.

2. Composition of polyurethane-edged mine screen

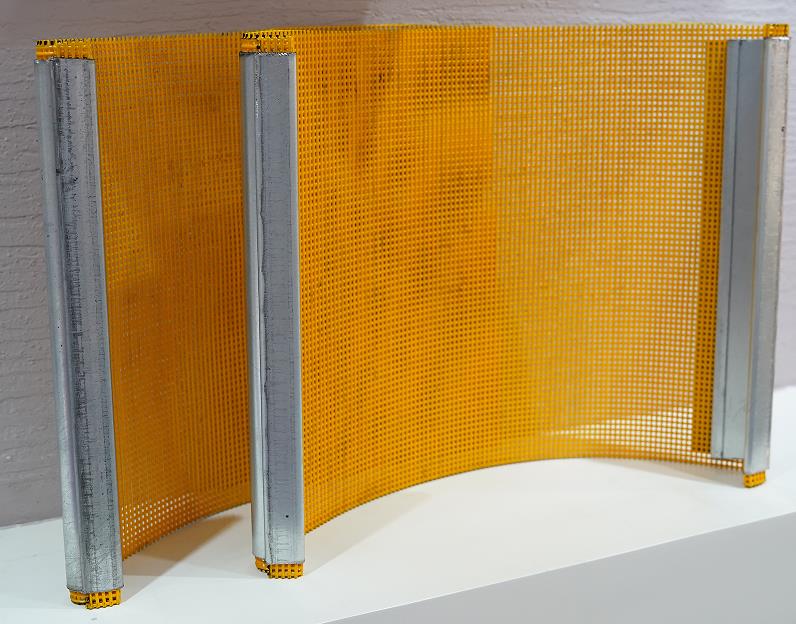

Typically constructed from a combination of wire mesh and polyurethane edges. The metal wire mesh is responsible for screening materials, while the polyurethane edge plays a role in fixing and supporting it. It also provides a buffering protective layer for the entire mesh surface to prevent damage caused by wear or impact, thus significantly extending the The service life of mine screen.

3. What are the advantages of polyurethane-edged mining screens?

1. Excellent wear resistance

Due to the wear-resistant properties of polyurethane, polyurethane-edged mining screens can withstand continuous friction and impact and are suitable for continuous screening of large quantities of materials.

A High mechanical strength: The polyurethane material itself has high tensile strength and tear resistance, which allows the screen made of it to maintain good performance when withstanding material impact and friction.

B Excellent elasticity: The polyurethane screen has good resilience, which can effectively alleviate the impact of materials, reduce wear and tear, and thereby extend the service life.

C. Stable structure: High-quality polyurethane screens usually have high surface finish and stable dimensions. These features help reduce the friction coefficient during operation, thereby improving wear resistance.

D Adapt to different environments: Polyurethane screens are suitable for both dry and wet application environments, and can maintain a long service life when handling hard materials.

E High temperature resistance: Although the upper limit of the ambient temperature for use of polyurethane screens is generally 45°C, it can maintain good wear resistance within this temperature range.

F Corrosion resistance: The oil-resistant and corrosion-resistant properties of the polyurethane material itself also help enhance the durability of the screen, allowing it to maintain wear-resistant properties in chemically aggressive environments.

2. Good sealing performance

The polyurethane edge design helps to improve the sealing performance of the mine screen and reduce the loss of fine particles, which is particularly important for applications that require high-precision screening.

3. Easy to clean and maintain

The polyurethane surface is smooth and difficult to adhere to materials, making it relatively easy to clean, which helps keep the mine screen clean and hygienic and reduces maintenance costs.

4. Environmental protection

As a non-toxic material, polyurethane is not only safe and harmless to operators, but also environmentally friendly and in line with the current sustainable development principles of industrial production.

5. High durability

The polyurethane material itself has excellent tensile and tear resistance, so even in extreme working environments, it can effectively prevent damage to the edges of the mine screen and ensure long-term and stable screening effects.

4. Practical application

Polyurethane edged mine screens are widely used in coal, metallurgy, building materials, chemical and other industries. Whether it is solid-liquid separation or material particle size control, it can perform excellent performance. Especially when dealing with some wet, sticky or corrosive substances, polyurethane edge mine screens show their unique advantages.

With the advancement of science and technology and the improvement of technology, the performance of polyurethane edge mine screens is also constantly improving. For example, by adjusting the formula and processing technology, customized mine screens that are more suitable for different working conditions can be produced to meet various special needs.

In general, polyurethane-edged mining screens play an important role in the field of modern industrial screening with their unique material characteristics and structural design. It not only improves work efficiency and product quality, but also reduces production costs and environmental risks. Therefore, for industrial enterprises that pursue efficiency and environmental protection, polyurethane edge mine screens are undoubtedly a choice worth considering.

In the future development, polyurethane edge mine screens will continue to innovate to adapt to more complex and diverse application needs. At the same time, its application will also promote technological progress and industrial upgrading of related industries, making greater contributions to our industrial development.