Heat treatment process of steel plate perforated screen

Steel plate perforated screen is a commonly used screening material It is mainly made of steel plate and has the characteristics of high aperture accuracy, corrosion resistance, wear resistance and high strength It is widely used in screening, filtratio

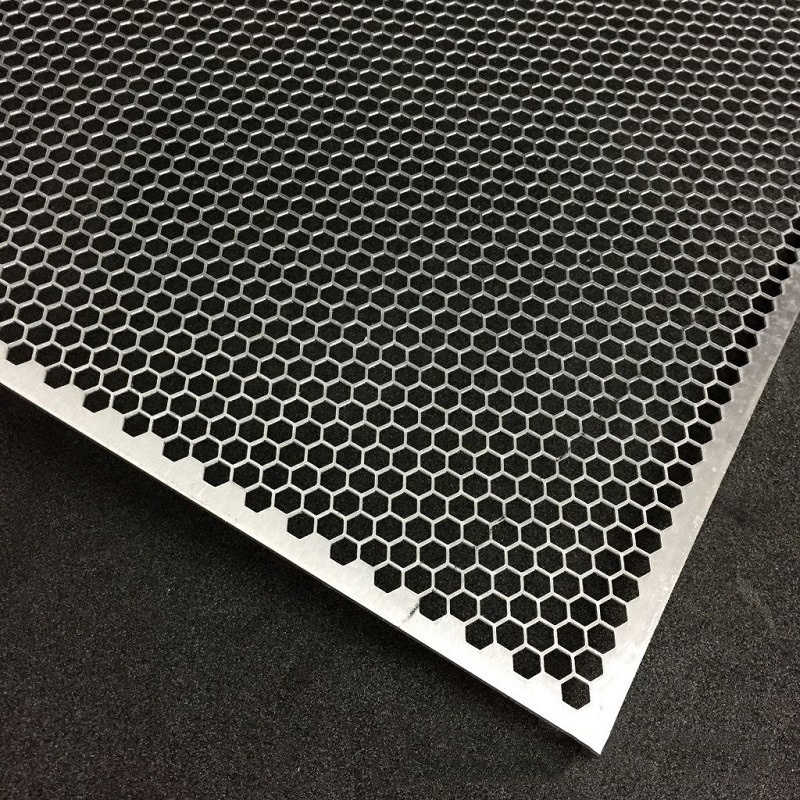

Steel plate perforated screen is a commonly used screening material. It is mainly made of steel plate and has the characteristics of high aperture accuracy, corrosion resistance, wear resistance and high strength. It is widely used in screening, filtration, screening, grading and other fields in mining, chemical, building materials, metallurgy and other industries. The heat treatment process of steel plate perforated screen has a great influence on its performance. Let's take a closer look.

The heat treatment process of steel plate perforated screen is generally divided into two steps: quenching and tempering. Quenching refers to heating the steel plate perforated screen to a certain temperature to make its structure undergo phase change, and then rapidly cooling it to change its structure into martensite. This can improve the hardness and strength of the steel plate perforated screen, but it will also increase its brittleness and make it prone to cracks and fractures. Therefore, tempering treatment is required to heat it to a certain temperature and then slowly cool it to make its structure change accordingly, thereby reducing its hardness and strength and improving its toughness and plasticity.

The heat treatment process of steel plate perforated screen needs to pay attention to the following points:

1. The heating temperature should be appropriate. If the heating temperature is too high, the grains will grow and the structure will be uneven, thus affecting the performance of the steel plate perforated screen; if the heating temperature is too low, the structure will not fully change and the expected hardness and strength will not be achieved.

2. The quenching medium should be selected appropriately. The quenching medium generally selects water, oil, salt water, etc. Improper selection will affect the performance of the steel plate perforated screen.

3. The tempering temperature and time should be appropriate. If the tempering temperature is too high, the hardness and strength of the steel plate perforated screen will decrease; if the tempering temperature is too low, its toughness and plasticity will be insufficient, and it will be easy to break and crack. The tempering time should also be adjusted according to the different materials. Generally speaking, the longer the time, the lower the hardness and strength of the steel plate perforated screen, and the higher the toughness and plasticity.

4. The heat treatment process should be well controlled. During the heat treatment process, it is necessary to control parameters such as heating speed, holding time, quenching speed, and tempering speed to ensure that the performance of the steel plate perforated screen meets the expected requirements.

In short, the heat treatment process of steel plate perforated screen has a great influence on its performance, and it needs to be adjusted and controlled according to the specific situation to ensure that its performance meets the expected requirements and improve its service life and efficiency.