How to do surface treatment for manganese steel woven screen?

With the development of economy, the application of manganese steel woven screen is spread across various fields, from cutting-edge technology, high-tech industries to food

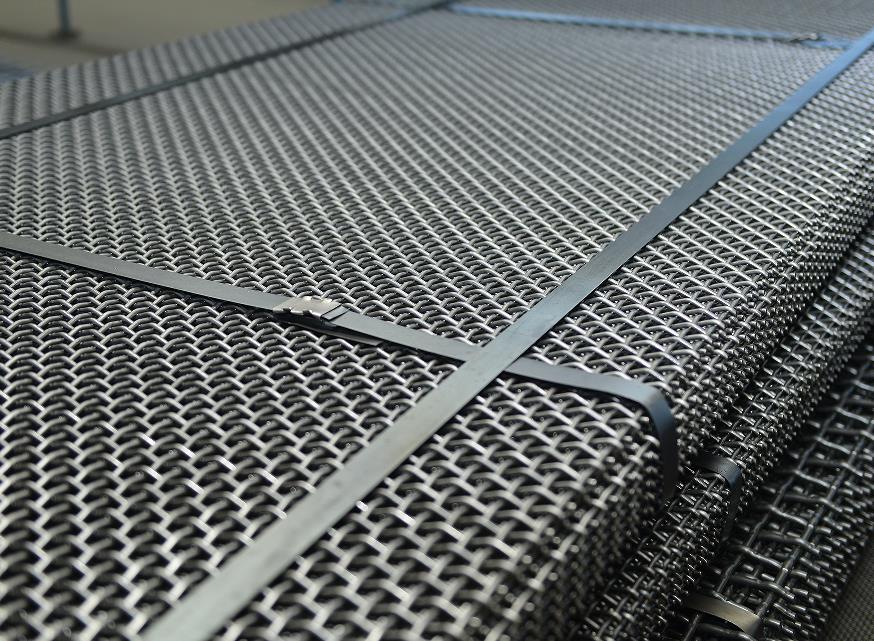

With the development of economy, the application of manganese steel woven screen is spread across various fields, from cutting-edge technology, high-tech industries to food, clothing, housing, transportation, and cultural life. Although this product is widely used by people, there are still some misunderstandings about its surface treatment, which affects the service life and appearance of the product.

When purchasing, some customers require that the mesh surface of manganese steel woven screen be pressed into a certain special shape. This is a difficult production process, which requires that there should be no changes in the mesh production. Slight changes will cause the mesh plate to deform. Some users often have some misunderstandings about the surface treatment of this product, thinking that there are only one or two treatment methods, and there is no special attention. In fact, there are many ways to treat the surface. The faster treatment methods are cold galvanizing and plastic spraying. The more common treatment methods are plastic dipping. If the anti-corrosion performance is required, hot galvanizing and then plastic dipping are used. This product has a long service life and good wear resistance. Because the skeleton material of the screen is steel wire, and the material has a very good elastic modulus, its bearing capacity exceeds that of other screens. When producing the screen, the raw materials are specially treated to ensure that they will never delaminate during use. This product is highly professional and practical, and is suitable for any type of vibrating screen machine. It can screen any items in the range of 0.1MM-170MM, and the screening efficiency is not affected whether the items are dry or wet.

Due to the high efficiency and low pore blocking rate of manganese steel woven screen, the water seepage function can avoid the adhesion of wet fine particles, and it can be used for the screening of wet fine particles.