How to choose polyurethane screen and manganese steel screen?

In industrial production, screening materials is a crucial link, and the choice of screen material is directly related to screening efficiency, cost control and product quality

In industrial production, screening materials is a crucial link, and the choice of screen material is directly related to screening efficiency, cost control and product quality. At present, polyurethane screen and manganese steel screen are the two mainstream materials in the screening field, each showing unique advantages, which makes enterprises think about it when choosing.

Polyurethane screen stands out for its excellent wear resistance and impact resistance. This polymer material can remain stable under harsh working conditions, is water-resistant, oil-resistant, and not easily deformed by friction or impact, thus ensuring long-term and stable screening effect. The weight of polyurethane screen is light, which greatly reduces the energy consumption and load of the machine and extends the service life of the screening machine. In addition, the service life of polyurethane screen is long, which is several to dozens of times that of manganese steel screen, which greatly reduces the amount of maintenance and replacement in later use and improves economic benefits. At the same time, polyurethane screen has good plasticity and can easily adapt to various complex shapes to meet diverse screening needs.

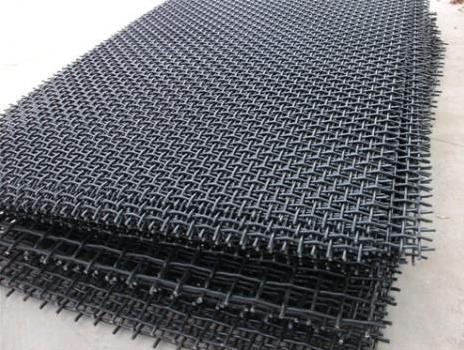

However, manganese steel screen also has its unique features. Manganese steel screen is known for its high strength and high rigidity, and is a "tough guy" in the screening industry. It has high strength and wear resistance, can withstand high loads and high temperatures, is not easy to deform and damage, has high screening efficiency and long service life. The abrasion resistance and rust resistance of manganese steel further reduce maintenance costs and reduce downtime caused by frequent replacement. Although the initial investment of manganese steel screen may be slightly lower than that of polyurethane screen, its long-term stability and low maintenance cost make the total cost of ownership more competitive. In addition, the structure of manganese steel screen is simple, easy to disassemble, easy to clean and replace, thus reducing maintenance costs.

In practical applications, the two types of screens have their own uses. Polyurethane screens have excellent performance in quick returns and flexible applications due to their low cost, easy processing and strong adaptability. It is widely used in vibrating screens in mining, coal, chemical, construction and other departments as a fine-grained grade screen for bulk materials, especially suitable for screening and grading of wet fine-grained materials. Manganese steel screens, with their high strength, long life and low maintenance costs, dominate in heavy-load and high-demand application scenarios. It is often used for screening and filtering of materials such as coal, ore, and grain in the industrial field, as well as for screening of building materials such as sand and gravel in the construction field.

So, when screening materials, should we choose polyurethane screen or manganese steel screen? This requires comprehensive consideration of multiple factors such as specific application scenarios, economic benefits, environmental impact and sustainable development. If you pursue long-term stability and economic benefits, and the screening environment is relatively harsh, then polyurethane screen is undoubtedly a wise choice. If the screening workload is large, the temperature is high, and it needs to withstand a large impact force, then manganese steel screen is more competent for this task.

In summary, polyurethane screen and manganese steel screen have their own advantages, and the choice of which screen material should be based on actual needs. In the future, with the continuous advancement of screening technology and the continuous development of materials science, I believe that more high-performance and environmentally friendly screen materials will emerge, bringing more possibilities for industrial production.