How to choose the appropriate manganese steel anti-blocking screen specifications according to needs

The specifications of manganese steel anti-blocking screens include screen hole size, wire diameter, screen size, plate thickness and hole type The screen hole size can be customized between 0 5mm and 100mm

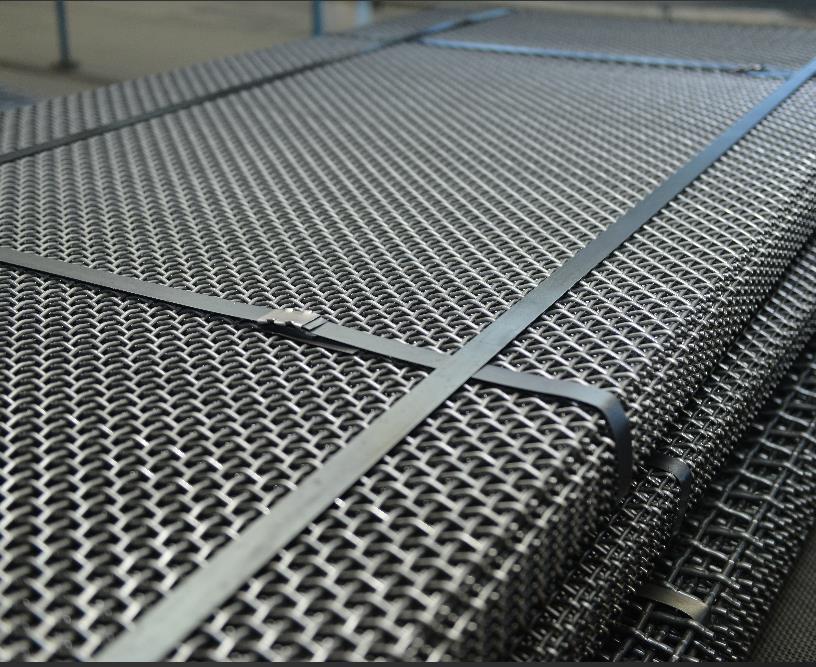

The specifications of manganese steel anti-blocking screens include screen hole size, wire diameter, screen size, plate thickness and hole type. The screen hole size can be customized between 0.5mm and 100mm. The wire diameter usually ranges from 1.5mm to 16mm, and the thickness directly affects the wear resistance and impact resistance of the screen. Common screen sizes range from 0.5mm to 100mm, which can be customized according to actual needs. The plate thickness generally ranges from 1mm to 20mm, and the working environment and load-bearing capacity need to be considered when choosing. The advantage of manganese steel anti-blocking screens is their anti-blocking performance, which is suitable for screening materials that are easy to block holes. The price of this screen is relatively high, due to special materials, special processing technology, glue reinforcement treatment and packaging and delivery requirements. Make sure to select screens of appropriate specifications, and install and maintain them correctly to extend their service life.

The specifications of manganese steel anti-blocking screen include mesh size, wire diameter, mesh size, plate thickness and hole type, which can be customized according to different usage requirements. Specifically:

1. Mesh size:

The mesh size of manganese steel anti-blocking screen is usually between 0.5mm and 100mm. According to different screening requirements, the mesh size can be customized to adapt to the screening of materials of different particle sizes. According to the characteristics of the material and the screening accuracy requirements, the mesh shape can also be selected in various forms such as square holes, rectangular holes, round holes, diamond holes or hexagonal holes.

2. Mesh wire diameter:

The mesh wire diameter usually ranges from 1.5mm to 16mm. The appropriate diameter is selected according to the actual application scenario and the wearability of the material being processed. The thickness of the mesh wire directly affects the wear resistance and impact resistance of the screen. The thicker wire diameter is suitable for processing more abrasive materials.

3. Screen size:

Common screen sizes generally range from 0.5mm to 100mm, including 1m×2m, 1.5m×3m, 2m×4m, etc., and the specific size can be customized according to actual needs. The size of the screen needs to be selected based on the size of the vibrating screen and the installation method to ensure that the screen can be installed intact on the screen machine and can work effectively.

4. Plate thickness:

The plate thickness generally ranges from 1mm to 20mm. When selecting, the working environment and bearing capacity of the screen need to be considered.

5. Hole type:

The hole type generally includes square holes, rectangular holes, round holes, diamond holes, hexagonal holes and other forms.

Screens with thicker plates have better strength and durability, but may also increase cost and weight.

When selecting a manganese steel anti-blocking screen, factors such as the screen hole size, wire diameter, screen size and plate thickness should be fully considered to ensure that the selected screen can meet specific usage requirements and have a long service life. Correct installation and maintenance of the screen is also the key to ensure its performance and extend its service life. In addition, due to its special hole structure and material requirements, the price of manganese steel anti-blocking screen is higher than that of general manganese steel woven screen. The main advantage of this screen is its anti-blocking performance, which is suitable for screening materials that are easy to block holes. The reasons for its high price include the special materials used (such as Beka manganese steel), special processing technology (such as the special arrangement of warp and weft screen bars), glue reinforcement treatment, and higher packaging and delivery requirements.