The Role of Self-Cleaning Harp Screens in Screening Efficiency

Self-cleaning harp screens are a game-changer in industries such as mining, aggregate, and recycling, where fine and sticky materials can clog traditional screening surfaces

Self-cleaning harp screens are a game-changer in industries such as mining, aggregate, and recycling, where fine and sticky materials can clog traditional screening surfaces. Their innovative design prevents blinding and clogging, ensuring optimal performance and maximizing productivity.

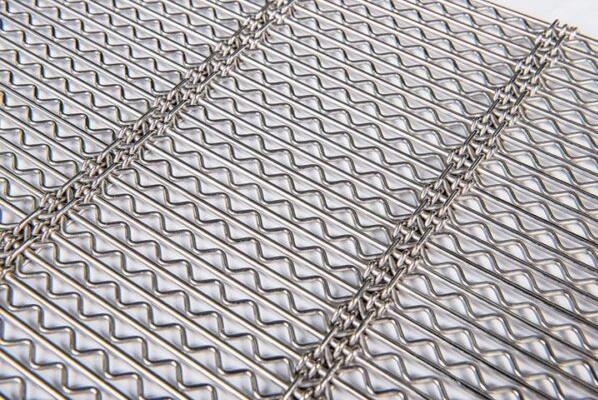

The primary function of self-cleaning harp screens is to improve material throughput by keeping the screen surface clear of debris. These screens feature flexible wires that vibrate independently, allowing sticky or fine particles to pass through without obstructing the screen. This unique self-cleaning mechanism ensures that the screening process remains efficient, even in challenging conditions.

Durability is another key benefit of self-cleaning harp screens. Made from high-tensile steel or polyurethane, these screens are designed to withstand heavy loads and abrasive materials, extending the lifespan of screening equipment and reducing the need for frequent replacements.

In addition to boosting productivity, self-cleaning harp screens reduce maintenance downtime. Traditional screens often require manual cleaning or replacements due to clogging, but with self-cleaning technology, operators can enjoy longer operational cycles and lower maintenance costs.

Moreover, these screens are versatile, suitable for both dry and wet screening processes. They are commonly used in industries that deal with difficult-to-screen materials, including sand, gravel, coal, and other mineral processing applications.

In summary, self-cleaning harp screens play a crucial role in enhancing screening efficiency, increasing equipment lifespan, and reducing maintenance challenges. Their ability to prevent clogging and improve material flow makes them a valuable asset in demanding industrial environments.