The Role of Polyurethane Flip Flow Screen Mesh in Screening Applications

Polyurethane Flip Flow Screen Mesh has revolutionized screening processes in industries like mining, construction, and recycling

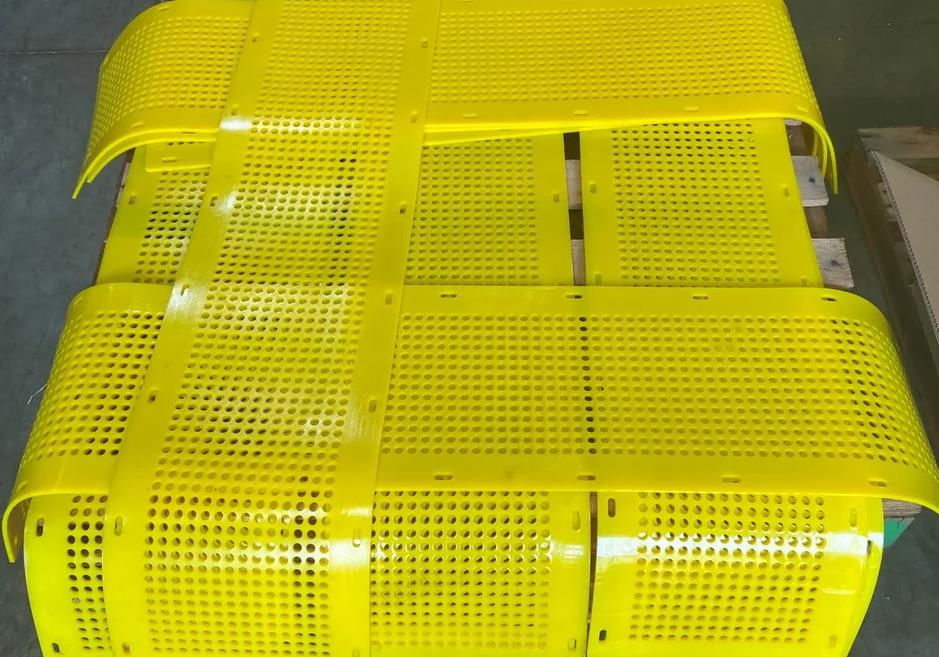

Polyurethane Flip Flow Screen Mesh has revolutionized screening processes in industries like mining, construction, and recycling. Its unique design and material properties make it an essential tool for handling difficult-to-screen materials, such as wet, sticky, or fine particles that would clog or blind traditional screens.

One of the primary roles of polyurethane flip flow screen mesh is its ability to enhance material throughput. Unlike static screening systems, flip flow screens use dynamic motion to continually flex the mesh. This constant movement helps prevent clogging and blinding, allowing materials to flow through more efficiently, even in challenging conditions.

Durability is another major advantage of polyurethane flip flow screen mesh. The polyurethane material is highly resistant to abrasion, chemicals, and wear, which makes it ideal for harsh environments. Its flexibility ensures that the mesh returns to its original shape after deformation, further extending its lifespan and reducing the need for frequent replacements.

In addition to its durability and efficiency, the flip flow mechanism significantly reduces downtime and maintenance. Operators benefit from lower operational costs and higher productivity, as the need for cleaning or replacing clogged screens is minimized. Polyurethane flip flow mesh also reduces noise levels during operation, creating a more comfortable working environment.

In conclusion, polyurethane flip flow screen mesh plays a critical role in improving screening efficiency, increasing equipment lifespan, and reducing operational challenges in industries with demanding material handling needs. Its versatility and durability make it the ideal solution for improving the performance of screening processes.