What is the cause of damage to the vibration screen?

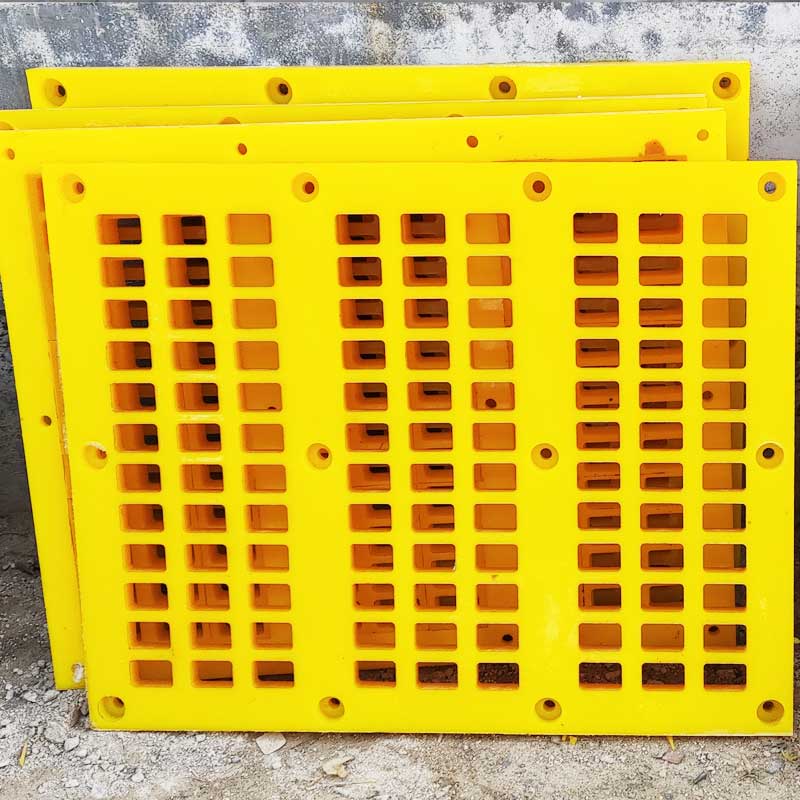

The vibration screen is a supporting equipment for the sand making production line, which is the main component of heavy machinery

The vibration screen is a supporting equipment for the sand making production line, which is the main component of heavy machinery. During the use process, it will inevitably cause damage. This restriction factors to remove the service life of the sieve network will also cause some serious problems that cause this situation to appear, and you need to pay attention.

The first is that the tension of the vibration screen is not enough. This is a problem of installation. The screening network is not in place. As a result, the mesh surface is relaxed and the tension is insufficient. It was broken at the edge of the screen or the edge of the edge.

Another reason is that the quality of the vibration screen itself is unqualified. The screening network requires the upper and lower layers. The two layers must be closely fitted. If the two layers do not fit tightly, the drilling dandruff cannot be discharged in time, which will damage the screen.

Another reason is that there is an error in the direction of the vibration production line. This is mainly the error that the staff may have. The operator's experience of using the single -axis vibration screen or a straight -line vibration sieve. It is not applicable to the flat ellipse vibration screen, which causes damage to the screen network.

The above is the main reason for the damage to the vibration screen. It must be paid attention to ensure the safety of the use of the screen and make it better create benefits for us.