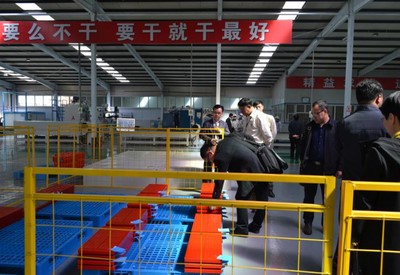

Red Star has been a company focusing on engineering and manufacturing of screening media used in mining and aggregate industries for over 30 years. Our new plant of 50,000 square meters combines polyurethane screen & self-cleaning screen workshop, woven wire screen workshop, wedge wire screen workshop and raw material & wire drawing workshop. From our entrepreneurial beginning in 1989 to today, we have been granted 18 national patents and all our products are manufactured to meet or exceed the standards prescribed by European and North American standards, and certified in accordance with ISO Quality Management System, Environmental Management System and Occupational Health & Safety Management System.

Red Star is committed to maintaining a leading position in global screen media market. To uphold the commitment we make, we work closely with our worldwide customers to make sure every screen is featured by robust structure, long wear life and precise opening size to help customers in increasing throughput while maintaining high screening accuracy.

Improving of the product quality and increasing of the production efficiency are closely tied to technologies and equipment. Red Star is the only domestic screening media manufacturer that has purchased and introduced North American and European advanced technologies and equipment, achieving automatic production of self-cleaning screens. Red Star invests heavily in new product developing, equipment refurbishing and technology upgrading every year. In 2016, we have reached a strategic cooperation with China University of Mining and Technology by establishing graduate student practice base and polymer engineering research center in our plant.

We strive for constant growth and innovation in mining and aggregate screening industry, aiming at offering the best product and service to our customers’ needs and creating additional value for their business.

Company View

Other types of screening media that could interest you

Shale shaker screens are mostly applied to the shale shakers with wedge fastening equipment The composite frames

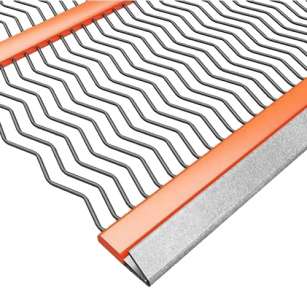

Made with crimped wires placed parallel to each other, best used for severe blinding application, large open area

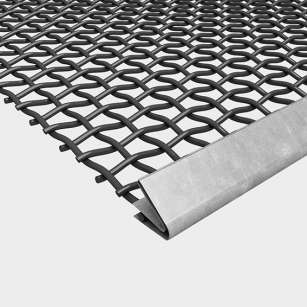

Known for its superior strength and durability, this mesh is ideal for heavy-duty applications, including vibrating

Polyurethane sieve plate has the characteristics of good wear resistance, long service life, high screening quality

DescriptionPolyurethane support strips are components used in vibrating screening equipment, typically employed to su

DescriptionIn mining machinery, U-bolts are commonly used to connect and secure various mechanical components, struc

For tensioning a wide range of screens, including woven screens with tensioning hooks and self-cleaning screens The

-- Easy installation: metallic hooks design makes it very easy to install or replace -- Long Lasting and Maximize